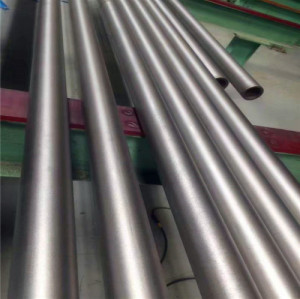

Cold Drawn Seamless Steel Tubes

Item specifics

- OD range:

- 10-250 mm

- WT range:

- 1-10 mm

- Delivery condition:

- BK, BKW, BKS, GBK, NBK

- Surface condition:

- Bright, Smooth

Review

Description

1. Description:

The cold rolled seamless tubes have closer dimensional tolerances, better surface finish and higher mechanical properties than the corresponding grades of hot finished seamless tubes.

2. Application:

High Precision Cold Rolled Seamless Steel Tube is used in automotive industry, and in the occasion where the high accuracy, brightness, cleanness of the tube are required.

3. Main Features:

l Superior surface finish

l High yield strength

l Dimensional accuracy and excellent micro-structure uniformity

l Enhanced machinability

l High strength to weight ratio

l Tight tolerances, resulting in reduced machine time

l Possible spiraling eccentricity inherent in product

4. Quality Standard:

DIN 2391 Seamless precision steel tube

BS EN 10305-1 Seamless cold drawn tubes

BS EN 10305-4 Seamless cold drawn tubes for hydraulic and pneumatic power systems

BS 6323-4 Cold finished seamless steel tube

ASTM A519 Seamless Carbon and alloy steel mechanical tubing

JIS G3441 Alloy Steel Tube for machine purpises

JIS G3445 Carbon steel tube for machine structural purposes

5. Chemical Composition(%):

Grade | C | Si | Mn | P | S | Cr | Mo |

St 35 (DIN1.0308) | 0.17 max | 0.35 max | 0.40 min | 0.025 max | 0.025 max | / | / |

St 52 (DIN1.0580) | 0.22 max | 0.55 max | 1.60 max | 0.025 max | 0.025 max | / | / |

CFS 4 | 0.25 max | 0.35 max | 1.20 max | 0.050 max | 0.050 max | / | / |

CFS 5 | 0.23 max | 0.50 max | 1.50 max | 0.050 max | 0.050 max | / | / |

CFS 10 | 0.26 max | 0.35 max | 0.80 max | 0.050 max | 0.050 max | 0.80-1.20 | 0.15-0.30 |

1020 | 0.18-0.25 | / | 0.30-0.60 | 0.040 max | 0.050 max | / | / |

1045 | 0.43-0.50 | / | 0.60-0.90 | 0.040 max | 0.050 max | / | / |

4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | 0.040 max | 0.040 max | 0.80-1.10 | 0.15-0.25 |

6. Delivery Conditions:

+C (BK) Hard. No final treatment after final cold rolling.

+LC (BKW) Soft. Final heat treatment is followed by a suitable drawing pass (limited reduction of area).

+SR (BKS) Stress Relieved. After final cold rolling, the tubes are stress relieved in a controlled atmosphere.

+A (GBK) Annealed. After final cold rolling, the tubes are annealed in a controlled atmosphere.

+N (NBK) Normalized. After final cold rolling, the tubes are normalized in a controlled atmosphere.

7. Mechanical Properties( T=20℃ if not differently stated ):

Grades | Delivery Conditions | Tensile Strength Rm (Mpa) | Yield Strength R2 (Mpa) | Elongation in the longitudinal direction Al (%) |

St 35 | +C (BK) | 480 min | / | 6 min |

St 35 | +LC (BKW) | 420 min | / | 10 min |

St 35 | +SR (BKS) | 420 min | 315 min | 14 min |

St 35 | +A (GBK) | 315 min | / | 25 min |

St 35 | +N (NBK) | 340-470 | 235 min | 25 min |

St 52 | +C (BK) | 640 min | / | 4 min |

St 52 | +LC (BKW) | 580 min | / | 7 min |

St 52 | +SR (BKS) | 580 min | 420 min | 10 min |

St 52 | +A (GBK) | 490 min | / | 22 min |

St 52 | +N (NBK) | 490-630 | 355 min | 22 min |

E235 | +C (BK) | 390 min | / | 7 min |

E235 | +A (GBK) | 315 min | / | 25 min |

E235 | +N (NBK) | 340-480 | 235 min | 25 min |

E355 | +C (BK) | 540 min | / | 5 min |

E355 | +A (GBK) | 450 min | / | 22 min |

E355 | +N (NBK) | 3490-630 | 355 min | 22 min |