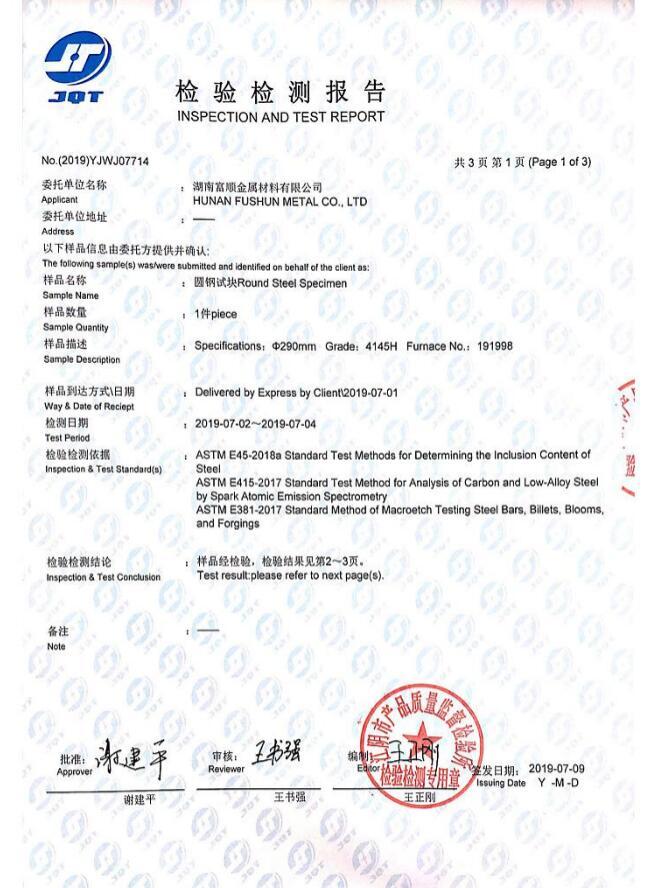

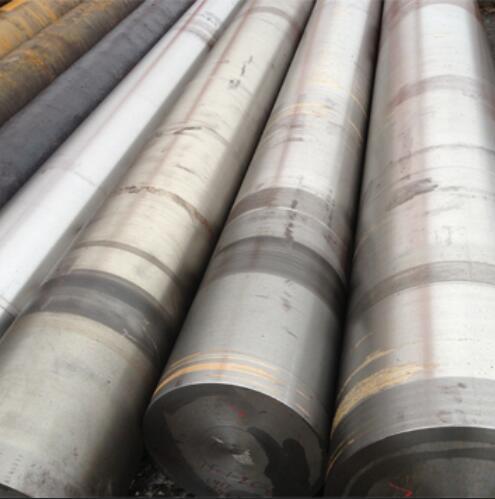

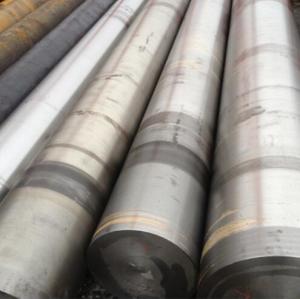

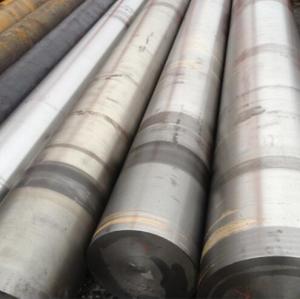

AISI SAE 4145H Hot Forged Alloy Steel Round Bar

- Price

- US $1400

- Model

- AISI/SAE 4145H solid bar

- MOQ

- 1 metric ton

Item specifics

- Steel grade

- AISI/SAE 4145H mod

- Applications

- drilled collars, connecting rods, shafts, gears

- Heat treatment

- Normalized,Quenching and Tmenpering

- Surface condition

- Black or bright surface

- Standard

- API 7-1

Review

Description

4145H Steel Bar Introduce:

4145H high tensile steel has good ductility, shock resistance and wear resistance.4145H modified conforms to API Spec 7.Typical uses are: drilled collars, connecting rods, shafts, gears

4145H Steel Related Specifications:

Australia, Germany, Great Britain, International API Spec 7, Japan

USA SAE J1268, UNS H41450, ASTM A304

Forging of 4145H

Heat to 1200 oC maximum, hold until temperature is uniform throughout the section. Do not forge below 950 oC.

Heat Treatment of 4145H

Annealing: Heat to 815 oC - 850 oC, hold until temperature is uniform throughout the section.

Hardening:Heat to 820 oC - 870 oC, hold until temperature is uniform throughout the section. Quench in oil as required.

Normalizing:Heat to 870 oC - 900 oC, hold until temperature is uniform throughout the section, soak for 10 - 15 minutes and cool in still air.

Tempering:Re-heat to 430 oC - 700 oC as required and according to properties required.

Welding of 4145H

Best results by common fusion or resistance methods. Do not weld by oxyacetylene.