What is Spheroidize Annealing

- Share

- Issue Time

- Apr 9,2018

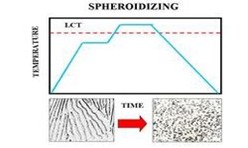

Spheroidize Annealing

Spheroidize annealing is applicable to steels which have more than 0.8% carbon. Parts are heated to between 1150°F and 1200°F and holding it at this temperature for a period of time to convert the microstructure. Essentially, cementite changes from a lamella formation to an alpha ferrite matrix with particles of spheroidal cementite (Fe3C). Spherodize annealing is generally done on parts which have been work hardened, to allow them to be further worked, either rolled in the case of coils, or drawn for wire. This resulting product has improved ductility and toughness with reduced hardness and strength. Spherodize annealing is normally carried out under a protective (endothermic) atmosphere to prevent oxidation and decarburization.

We can supply follows heat treatment services:

Normalizing, Annealing, Quenching, Tempering, Carburizing, Nitriding, High-frequency surface hardening and other processing services.