Baosteel breaks through the barrier of laser welding technology for hot-formed steel of aluminum-silicon coating

- Share

- From

- chinese steel

- publisher

- harris

- Issue Time

- Jun 18,2019

Summary

Baosteel breaks through the barrier of laser welding technology for hot-formed steel of aluminum-silicon coating

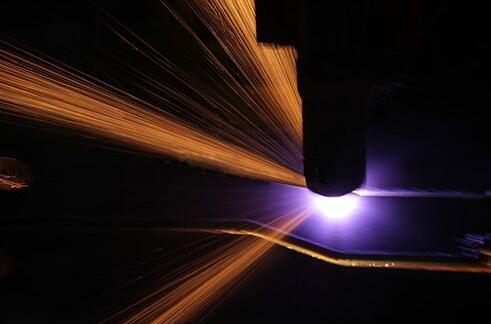

Recently, at the Baosteel Technology Show held in Germany, Baosteel Laser Tailoring Co., Ltd. released the world's first new technology for aluminum-silicon coated hot-formed steel welding.

This technology innovates the welding process and technology between 1500 MPa and 1500 MPa aluminum-silicon coated hot-formed steel. It can directly laser-weld the coated steel plate without removing the aluminum-silicon coating of hot-formed steel, breaking through the related patent technology. barrier.

Aluminium-silicon coated thermoformed steel has excellent resistance to high temperature oxidation. The surface of the steel sheet is not oxidized during hot stamping. It is widely used in the manufacture of thermoformed parts, but the high aluminum content in the coating enters the weld and the weld bead performance is deteriorated. . The welding method is to first remove the aluminum-silicon coating by laser ablation or other methods, and then perform welding. This method not only increases the plating ablation process, but also increases the equipment input cost, and the plating ablation speed is lower than the welding speed, which reduces the production efficiency and increases the production cost. At the same time, more dust is generated during the process of removing the plating, which requires centralized collection. And processing, increasing production support costs.

On the basis of achieving the laser welding and mass production of 1500 MPa+ low-strength thermoformed aluminum-silicon materials, Baosteel's domestic and overseas research team continued to exert force on laser welding of 1500 MPa+1500 MPa aluminum-silicon thermoforming materials. . Baosteel Laser Tailoring Co., Ltd. in Germany conducts research and development of materials, processes and equipment based on mass production stability; Baosteel Academia Sinica, based in Shanghai, focuses on “double new solutions” – new welding wire + new welding Process development. After continuous and arduous research, the research team at Baosteel Co., Ltd. at home and abroad has achieved the goal of successful industrialization test.

Among them, the Central Research Institute of Baosteel Co., Ltd. began to study the laser tailoring technology of 1500 MPa+1500 MPa and other strength aluminum-silicon coated steel from 2017, and successfully developed new techniques and new technologies suitable for the welding of aluminum-silicon coated plates. A breakthrough in the “double new solution” was achieved, and the microstructure and grain size of the weld were effectively controlled.

The new laser welding technology of 1500 MPa + 1500 MPa aluminum-silicon plating thermoformed material released by Baosteel Laser Tailoring Co., Ltd. was carried out by the company Yana von Hyde and her team after more than 5 years of batch trials. And systematic research on materials, processes and equipment, and finally developed successfully. The technology is more environmentally friendly and more in line with the vision and goals of laser tailor welding as a solution to promote lightweight vehicles.