440C 1.4125 SUS440C Stainless Steel Flat

- Model

- 440C 1.4125 SUS440C

Item specifics

- Width

- 40-200mm

- Surface condition

- Black, Blasted,

- Delivery Condition

- Annealed, Hot rolled+annealed, Cold drawn only

Review

Description

Introduction of 440C Steel:

440C stainless steel is a high carbon martensitic stainless steel. It has high strength, moderate corrosion resistance, and good hardness and wear resistance.

Applications of 440C Steel:

Suitable for applications requiring a combination of excellent wear resistance with moderate corrosion resistance, 440C stainless steel is commonly used in the oil and gas, marine, food and medical industries. Typical applications are pumps, valve components, bearings, knives, surgical tools, cutlery, bearings and races.

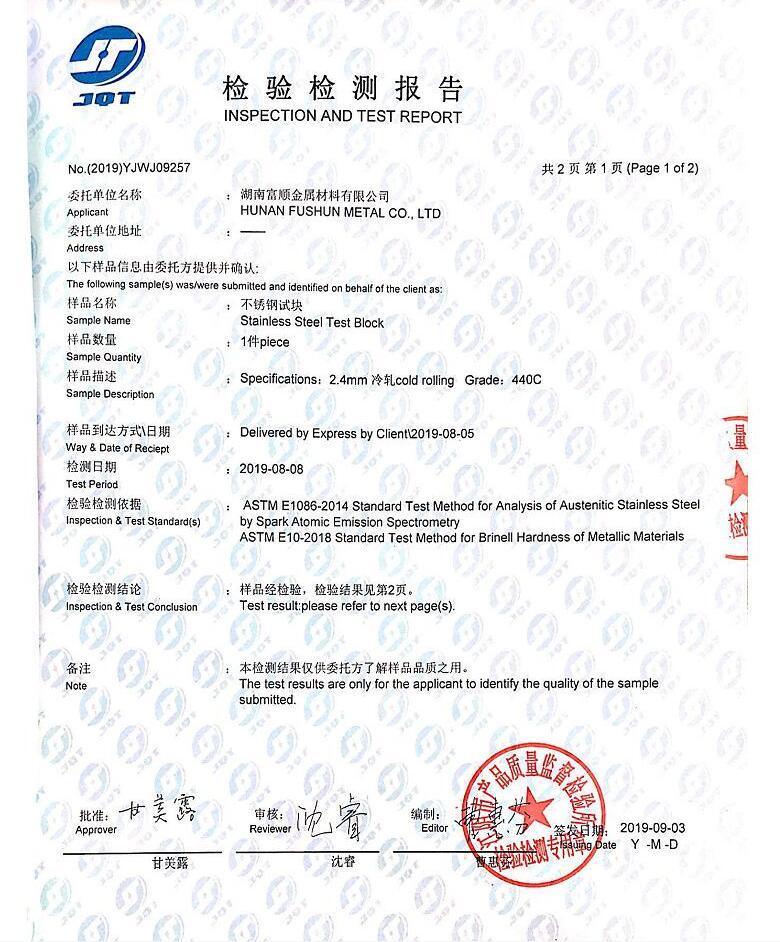

Chemical Composition of 440C Steel:

Grade | C | Mn | P | S | Si | Cr | Mo |

440C | 0.95-1.20 | 1.0 max | 0.040 max | 0.030 max | 1.0 max | 16.00-18.00 | 0.75 max |

Similar Grade: 1.4125, X105CrMo17, UNS S44004, 440C

Shape: Round, Flat, Square.

Steel-making Condition: EF, EF/EAF+LF+VD, EF/EAF+ESR

Delivery Condition:Annealed, Hot rolled+annealed, Cold drawn only

Surface Condition: Black, Blasted,Polished

Hardness (HB): 285 max

Heat Treatment

l Hot Working:440C stainless steel is pre-heated at 760°C (1400°F). Temperature can be increased up to 1038-1204°C (1900-2200°F). It should not be heated below 927°C (1700°F). It is then slowly cooled at room temperature and fully annealed.

l Cold Working: 440C stainless steel is slightly cold workable using common practices.

l Forging: 440C stainless steel can be forged by heating slowly and uniformly to 1050-1150°C, allowing sufficient time for the steel to become heated through. Ensure not to overheat as this can cause a loss of toughness and ductility. Do not forge below 900°C reheating if necessary. After forging cool slowly in furnace or thermoinsulating material, then anneal immediately. Air cooling after forging may cause cracking.

l Annealing: 440C stainless steel is annealed at 843-871°C (1550-1600°F) followed by slowly cooling in the furnace.

l Hardening: 440C stainless steel can be hardened by heating at 760°C (1400°F). Temperature can be increased up to 1010°C (1850°F) followed by cooling in air or oil.

l Tempering:440C stainless steel can be tempered by soaking at 148°C (300°F).