1.3343 M2 High Speed Steel Sheet and Plate

- Model

- 1.3343, M2

Item specifics

- Thickness

- 1-16mm

- Width

- 810mm max

- shape

- Sheet, plate

- Surface Condition

- Black, Smooth, Bright

- Delivery Condtion

- Cold rolled+annealed, Hot rolled+annealed

Review

Description

Introduction:

1.3343/M2 steel is a general purpose molybdenum high speed steel. 1.3343/M2 steel is characterized by balanced combination of abrasion resistance, toughness and good red hardness. Due to its comparatively low carbon content, 1.3343/M2 steel has an excellent combination of toughness properties and abrasion resistance when properly hardened and tempered. 1.3343/M2steel is used in a wide used for all kinds of cutting tool, knife and punch and die applications.

Application:

HSS Circular Saw, Blade, Press Mould, Drills, End mill, Planer Knife, Chipper Knife, Slice Knife, Hss Square Tool Bits.

Chemical Composition:

Steel Grade | C | Si | Mn | P | S | Cr | Mo | W | V |

1.3343 | 0.86-0.94 | 0.45max | 0.4max | 0.03max | 0.030max | 3.8-4.5 | 4.7-5.2 | 5.9-6.7 | 1.7-2.4 |

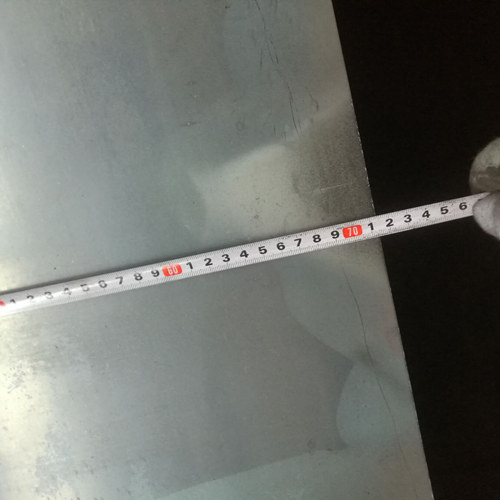

Size Range:

Thickness:1-16mm

Width:810mm max

Length:4000mm max

Tolerance of Size:

Thickness 1.5-2.5mm with Tolerance (-0,+0.15) --Cold rolled plate

Thickness 2.55-16.0mm with Tolerance (-0,+0.25) --Hot rolled plate

Tolerance of Amount: Above prices are based on actual weight.

Thermal Cycling:

In order to avoid decarburization, this grade should be annealed and/or hardened in a controlled neutral atmosphere, vacuum, or neutral salt furnace environment.

1. Annealing: Heat to 1600° F, soak thoroughly at heat. Furnace cool 25° F per hour to 900° F, air cool to room temperature. Approximate annealed hardness 241 Maximum Brinell.

2. Stress Relief of Unhardened Material: Heat slowly to 1200 to 1250° F. Soak for two hours per inch of thickness at heat. Slow cool (furnace cool if possible) to room temperature.

3. Hardening:

a. Preheating: Heat slowly to 1550° F, soak thoroughly, heat to 1850° F, soak thoroughly.

b. Hardening: Soak time in the furnace varies from a few minutes to a 15 minutes, depending tool size, heat capacity of the furnace, and the size of the charge.

– Heat to 2150 to 2200° F for max. toughness and minimum distortion.

– Heat to 2250 to 2275° F for max. hardness and abrasion resistance.

c. Quenching: For full hardness, oil quench to 150-200° F. Air quench to 150° F. When quenching in hot salt maintain the quench just above the Ms temperature. After equalizing withdraw parts from the hot salt and air cooled to 150° F.

d. Tempering: Double temper is mandatory, three tempers are sometimes preferred. Soak for 2 hours per inch of thickness. Air cool to room temperature between tempers. The best tempering range for hardness, strength and toughness is 1000 to 1050° F.