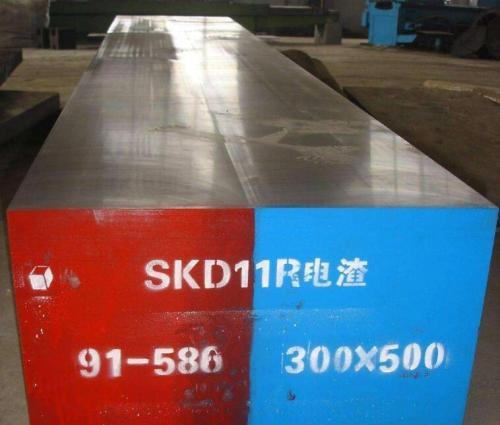

1.2379 D2 SKD11 Cold Work Tool Steel Plate For Cutter Blade

- Model

- 1.2379 D2 SKD1

Item specifics

- Thickness

- 1-16mm

- Width

- 810mm max

- shape

- Sheet, plate

- Surface Condition

- Black, Smooth, Bright

- Delivery Condtion

- Cold rolled+annealed, Hot rolled+annealed

Review

Description

Introduce:

The cutting, punching and shearing of metallic and non-metallic materials belong to the most demanding tasks cold-work tool steel tools are subjected to. Besides cutting and shearing, there are virtually no other applications where the tool's properties have such an influence on the process.

Standard:

Similar Grades:

ASTM | Material No. | DIN | EN |

D2 | 1.2379 | X155CrVMo12-1 | X160CrMoV121 |

Chemical Composition:

Grade | C | Mn | Si | P | S | Cr | Mo | V |

1.2379 | 1.45-1.6 | 0.20-0.60 | 0.10-0.6 | 0.03 max | 0.03 max | 11.0-13.0 | 0.7-1.0 | 0.7-1.0 |

Size Range:

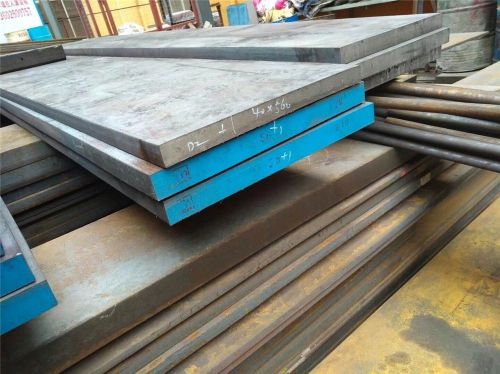

Thickness:1-16mm; Width:810mm max; Length:4000mm max

Tolerance of Size:

Thickness 1.5-2.5mm with Tolerance (-0,+0.15) --Cold rolled plate

Thickness 2.55-16.0mm with Tolerance (-0,+0.25) --Hot rolled plate

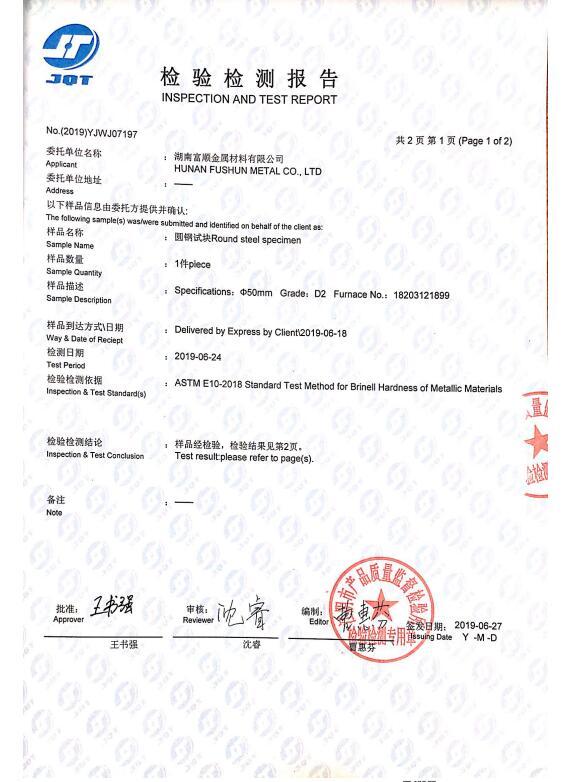

Steel-making Process: EF/EAF+LF+VD, EF/EAF+ESR

Delivery condition: Cold Rolled+Annealed, Hot Rolled+Annealed.

Surface condition: Acid Pickled or Shot Blastt

Heat treatment:

Annealed(+A) max: 255HB

Annealing: slow cooling at 650ºC-850ºCfurnace

Quenching: Preheat 650ºC~750ºC increased to 1010ºC, air-cooled, or into the 996ºC to keep the salt bath, then cooled.

Tempering: The cold work D2 tool steel general tempering temperature is 170ºC-190ºC , Double tempering of Double tempering of D2 tool steel is recommended.