AISI 4330V Hot Forged Alloy Steel Hollow Bar

- Model

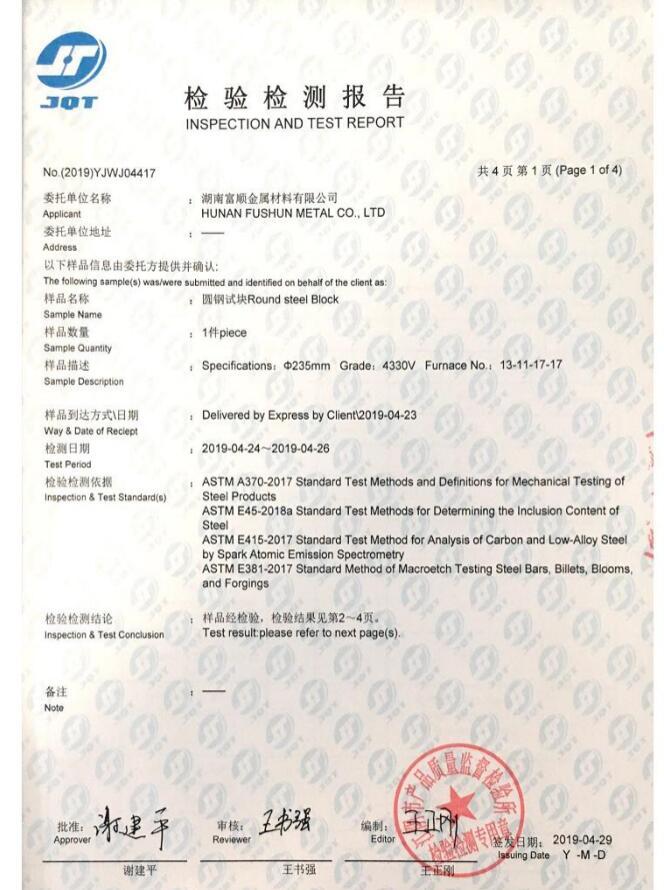

- AISI 4330V

Item specifics

- Heat treatment

- Quenching and Tempering

- Surface

- Bright or Black Surface

- Application

- Oil industry, Raise bore drill rods and drive subs

- Standard

- AMS 6427 AMS 6359 AMS6304 ASTM A646

Review

Description

AISI 4330V Steel

AISI 4330, is a fine-grained, medium carbon, chromium-nickel-molybdenum alloy steel. AISI 4330V is a modification of the 4330 alloy steel grade, with hardenability and other characteristics improved by the addition of vanadium. Alloy Steel 4330V offers good formability which is used for those that require a good combination of strength and impact resistance.

Relevant Standards

Applications

Raise bore drill rods and drive subs, gears, aircraft landing gear, axles or shafts for power transmission.

Chemicals and Physical

C | Mn max | Si max | Cr | Mo | Ni | P max | S max | V |

0.2-0.30 | 1.0% | 0.80 | 0.40-0.60 | 0.30-0.50 | 1-1.5 | 0.025 | 0.010 | 0.05-0.10 |

Tensile strength: 130,000 psi

Yield strength:115,000 psi

Elongation at break (In 50 mm): ≥ 16.0 %

Hardness HBW: 321 - 375