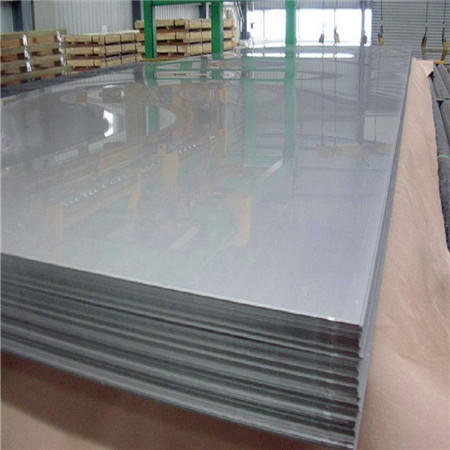

1.4112 X90CrMoV18 UNS S44003 440B Martensitic Stainless Steel Plate Sheet

- Model

- 1.4112 X90CrMoV18 UNS S44003 440B

Item specifics

- Thickness

- 1-16mm

- Width

- 1500mm max

- Surface Condition

- Black, Smooth, Bright

- Delivery Condtion

- Cold rolled+annealed, Hot rolled+annealed

Review

Description

Application:

Suitable for applications requiring a combination of excellent wear resistance with moderate corrosion resistance. 440B stainless steel is commonly used in the oil, gas, marine, food and medical industries. Typical applications include valve components, knives, bearings, surgical tools and cutlery.

Introduction:

440B stainless steel is a high carbon martensitic stainless steel containing good strength, moderate corrosion resistance and ability to obtain and maintain wear resistance and excellent resistance.

Feature:

Welding: Welding is not generally recommended for grade 440B stainless steel as it tends to harden in air. If this steel grade is welded the recommended temperature is 260°C (500°F) and for the post weld treatment the recommended temperature is 732-760°C (1350-1400°F). The post weld treatment should take place for 6 h and then the material should be cooled slowly in a furnace to avoid cracking. Similar high heat inputs and filler metal should be used during operations.

Machinability: 440B stainless steel is best machined in the annealed condition. Chip breakers are used to handle tough, stringy chips of grade 440B stainless steel. Ceramic or carbide tooling is best suited for this grade 440B stainless steel.

Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Product Details:

Shape: Sheet, Plate

Steel-making Process: EF/EAF+LF+VD, EF/EAF+ESR

Delivery condition: Cold Rolled+Annealed, Hot Rolled+Annealed.

Surface condition: Black, Smooth, Bright

Standard: BS EN ISO 4957, ASTM A600

Size Range:Thickness:1-16mm Width:810mm max Length:4000mm max

Tolerance of Size: Thickness 1.5-2.5mm with Tolerance (-0,+0.15) --Cold rolled plate; Thickness 2.55-16.0mm with Tolerance (-0,+0.25) --Hot rolled plate

Tolerance of Amount: Above prices are based on actual weight.

Packing: IN BUNDLES, AND IN CONTAINER 20 FEET.

HEAT TREATMENT:

Hot Working:Hot working for grade 440B stainless steel takes place by pre-heating the steel to 760°C (1400°F) which is then followed by slowly increasing the temperature range to 1038-1204°C (1900-2200°F). After the hot working process, the material is then cooled slowly at room temperature followed by complete annealing.

Cold Working: 440B stainless steel can be slightly cold worked by common cold working methods.

Forging:Heat slowly and uniformly to 1180°C, allowing sufficient time for the steel to become heated through. Be careful not to overheat as this can cause a loss of toughness and ductility. Do not forge below 1010°C reheating if necessary. After forging cool slowly in furnace or thermoinsulating material, then anneal immediately. Air cooling after forging 440B may cause cracking.

Annealing: 440B stainless steel is annealed at 843-871°C (1550-1600°F) and then cooled very slowly in a furnace.

Hardening: 440B stainless steel is heated at 760°C (1400°F), soaked at 1010°C (1850°F) and finally cooled in oil or air.

Tempering: 440B stainless steel is tempered at 148°C (300°F) to obtain maximum properties and the maximum hardness that can be obtained is RC58.