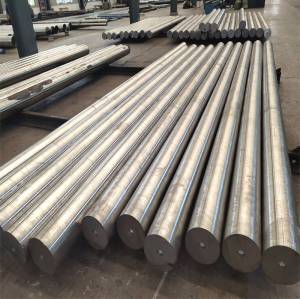

440B 1.4112 SUS440B Stainless Steel Bar

- Model

- 1.4112 X90CrMoV18 UNS S44003 440B

Item specifics

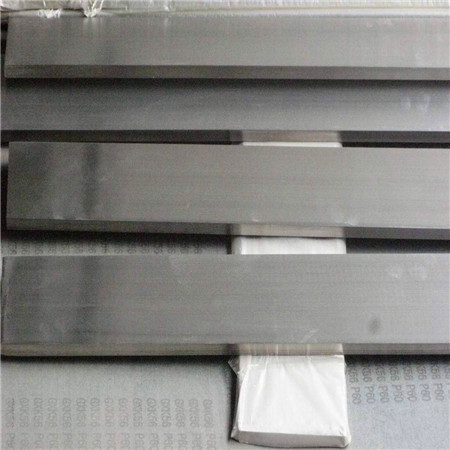

- Width Range

- 20-300mm

- Thickness Range

- 5-60mm

- Delivery Condition

- Cold drawn only or annealed

- Surface Condition

- Bright

Review

Description

Introduction

440B stainless steel is a high carbon martensitic stainless steel containing good strength, moderate corrosion resistance and ability to obtain and maintain wear resistance and excellent resistance.

Applications

Suitable for applications requiring a combination of excellent wear resistance with moderate corrosion resistance. 440B stainless steel is commonly used in the oil, gas, marine, food and medical industries. Typical applications include valve components, knives, bearings, surgical tools and cutlery.

Steel Grade | C | Si | Mn | P | S | Cr | Mo |

440B | 0.75-0.95 | 1.0 max | 1.0 max | 0.040 max | 0.030 max | 16.0-18.0 | 0.75 max |

Heat Treatment

Annealing:

440B stainless steel is annealed at 843-871°C (1550-1600°F) and then cooled very slowly in a furnace. Hardening:

440B stainless steel is heated at 760°C (1400°F), soaked at 1010°C (1850°F) and finally cooled in oil or air. Tempering:

440B stainless steel is tempered at 148°C (300°F) to obtain maximum properties and the maximum hardness that can be obtained is RC58.