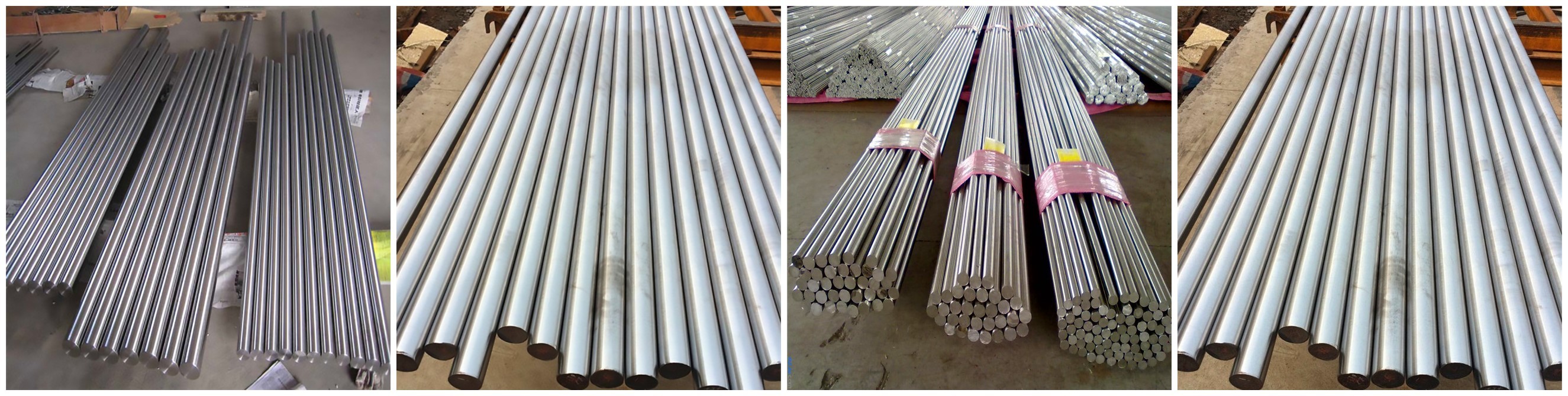

1.0036 St34-2 Gr.C S235JRG1 Bright Steel Round Bar

- Model

- 1.0036 St34-2 Gr.C S235JRG1

Item specifics

- diameter range

- 10-200mm

- length range

- 1-9 meter

- process

- cold drawn

- surface

- bright

Review

Description

Applications

Our profiles range in cross sectional areas that fit within a 0.032" to 2.000" diameter circle. Depending upon the profile cross sectional area, profile configuration and customer requirements, we deliver these profiles in a wide variety of forms that include catch weight and pancake wound coils, exact length and random mill length bars, deburred and non-deburred saw cut pieces, as well as adiabatic sheared pieces for larger volume requirements. Precision cold drawing controls allow us to offer linear dimensional tolerances that range from our standard +/- 0.002" to an optional +/- 0.0005". For cold rolled profiles we offer standard dimensional tolerances of +/- 0.002 on thickness and +/- 0.005" on width.

Size and Delivery

Round: .028”to3.00”(5-150mm)

Flat/Rectangles:width from .125”to5.00” Thickness from.125”to2.00”

Square: .028”to2.5”(10-150mm)

Hexagon: .028”to2.50”(5-90mm)

Centerless ground&Polished round bar: .812”to2.00”

Custom Engineered Special Steel Profile Shapes:.28”to3.00”

Tolerance: h8, h9, h10, h11

Straightness:0.5-1mm/meter

Roughness:Ra≤0.32μm, Rz≤1.6μm

Chemical Component

GRADE | Chemical Component % | ||||

C | Si | Mn | P | S | |

S 10 C | 0.08~0.13 | 0.15~0.35 | 0.30~0.60 | <0.030 | <0.035 |

S 12 C | 0.10~0.15 | ||||

S 15 C | 0.13~0.18 | ||||

S 17 C | 0.15~0.20 | ||||

S 20 C | 0.18~0.23 | ||||

S 22 C | 0.20~0.25 | ||||

S 25 C | 0.22~0.28 | ||||

S 28 C | 0.25~0.31 | 0.60~0.90 | |||

S 30 C | 0.27~0.33 | ||||

S 33 C | 0.30~0.36 | ||||

S 35 C | 0.32~0.38 | ||||

S 38 C | 0.35~0.41 | ||||

S 40 C | 0.37~0.43 | ||||

S 43 C | 0.40~0.46 | ||||

S 45 C | 0.42~0.48 | ||||

S 48 C | 0.45~0.51 | ||||

S 50 C | 0.47~0.53 | ||||

S 53 C | 0.50~0.56 | ||||

S 55 C | 0.52~0.58 | ||||

S 58 C | 0.55~0.61 | ||||

S 09 CK | 0.07~0.12 | 0.15~0.35 | 0.30~0.60 | <0.025 | <0.025 |

S 15 CK | 0.13~0.18 | ||||

S 20 CK | 0.18~0.23 | ||||

Application

Bright steel bars are used in below stated sectors and industries:

• Automobile Industries: Automobile industry majorly requires bright bars as they are required in making nuts, bolts, shafts and all the constituents of engines. For this purpose special grade of bright bars are required.

• Heavy engineering Industries: used in making heavy machines and tools for manufacturing various products.

• Textile industry uses the bars for manufacturing machines required to make textiles

• Electric pumps and electric motors require bright steel bars

• Railway engines and coaches are made with usage of steel bright bars

• Army and defense sector require the bars for making arms and ammunitions

• Agricultural sector uses the bright bars to make machinery and equipment required for agriculture.

• Sports and health equipment are also crafted from bright steel bars

• Various types of machineries are manufactured, using bright bars

• Splendid decorative furniture and lamps are fabricated out of them

• These steel bars are used in manufacturing gears, bearings and hinges

• All the fixtures, tools and hoses are made with usage of bright steel bars

• Cold headed components are also drafted from the bright bars

• Bright steel bars are also used in the food processing industry for manufacturing machines.

• Oil and petroleum industry requires bright steel bars

• These bars are used during mining process

• Bright bars are used making conveyor shafts

Bright steel bars are massively used in producing mechanical parts owing to its paramount properties in mechanical and dimensional fields. These bars can be fabricated into any other customized shape, according to the demand of clients. Bright bars are processed in diverse materials like alloy steel, MS & carbon steel or tool and die steel.