Cr12MoV Cold Work Tool Steel

- Model

- Cr12MoV

Item specifics

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

Cr12MoV COLD WORK TOOL STEEL

Description

Cr12MoV steel is a kind of ledeburite cold work tool steel which developed from Cr12 steel, as the added content of Mo, V, and decrease of C, Cr12MoV have the advantage of Higher hardenability, hardness, wear resistance and small heat treatment distortion. It’s regularly be used in manufacturing cold mold with a heavy load, bulk production, and complex shape. Due to Cr12MoV is ledeburite steel, so its toughness is greatly influenced by the carbide morphology and distribution.

Cr12MoV Steel, steel hardenability, quenching and tempering the hardness, wear resistance and strength than that of high Cr12. Cross section used in the manufacture large, complex shape, working under arduous conditions, with a variety of Die and tools, such as die punching, trimming mold, piping die, deep drawing steel mold, circular saws, standards, tools and gauges, thread rolling die and so on.

Chemical composition% of Cr12MoV steel

C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) | Cu(%) |

1.45~1.70 | ≤0.40 | ≤0.40 | ≤0.030 | ≤0.030 | 11.00~12.50 | ≤0.20 | 0.40~0.60 | 0.15~0.30 | ≤0.30 |

Cr12MoV equivalents alloy steel

Steel | Country Code | C(%) | V(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) |

SKD11 | CNS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

Cr12MoV | GB | 1.45-1.70 | 0.15-0.30 | ≦0.4 | ≦0.4 | ≦0.03 | ≦0.03 | 11.0-12.5 |

SKD11 | JIS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

X165Cr-MoV12 | DIN | 1.55-1.75 | 0.1-0.5 | 0.25-0.40 | 0.2-0.4 | ≦0.03 | ≦0.03 | 11.0-12.0 |

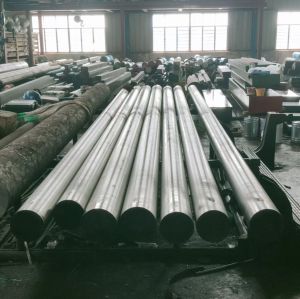

Cr12MoV steel Range of products

Product type | Products | Dimension | Processes | Deliver Status |

Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Heat treatment of Cr12MoV Alloy Steel

spheroidizing annealing:860℃ X 2h furnace cooling to 750℃ and then furnace cooling to 500-550℃, remove out and air cooling

Quenched + tempered:1100℃ X 20min step quenching + 700℃ X 1h tempering,remove out and air cooling

Quenching:1030℃ X 40min oil quenching(800℃ preheating,vacuum 2.5 pa) Tempering: 250℃ X 1h

Application

Cold work dies steel, steel hardenability, quenching, and tempering hardness, wear resistance, strength is higher than Cr12. Used in the manufacture of various cold stamping dies and tools with large cross- sections, complex shapes and heavy working conditions, such as punching die, trimming die, piping dies, deep drawing dies, circular saw, standard tools, and gauges Thread rolling die, etc