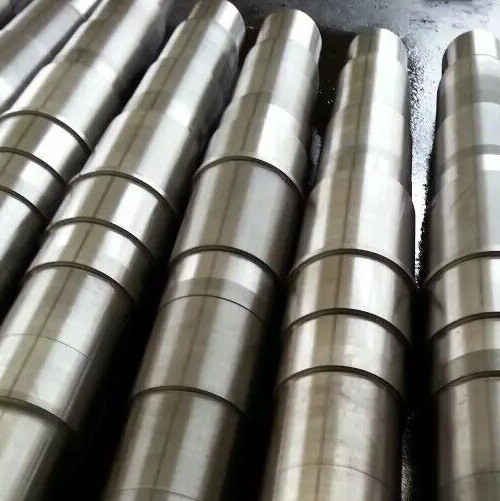

Work Roll Backup Roll Step Shaft Mian Shaft Forged Steel Roller

- Model

- Work roll/Backup roll/Step Shaft/Mian Shaft

Item specifics

- OD

- 200mm-2000mm

- Weight

- MAX 85 Tons

- working roll for hot rolled strip leveling rack

- Rack of tandem rolling mill for section, bar, wire rod and narrow strip

- Roll ring and roll of stretch reducing mill for se

- Work roll of hot rolled strip tempering rack and medium plate mill rack

Review

Description

High speed steel rolls, produced by horizontal centrifugal casting process, are all compound rolls with high speed steel as the work layer and nodular iron as the core. The material of HSS contains plenty of alloyed elements such as Mo, Ni, Cr,etc. The high hardened eutectic carbides & second carbides, evenly distributed in tempered martensitic matrix, make the wear and thermal cracking resistance very excellent. besides, the resistance to surface roughing is also good. In condition of hot rolling, the contact points between steel strip and the work rolls can form a thin adherent oxide film on the roll surface, which plays a good role in the wear features and the quality of the strip surface.

Application :

working roll for hot rolled strip leveling rack

Rack of tandem rolling mill for section, bar, wire rod and narrow strip

Roll ring and roll of stretch reducing mill for seamless steel tube

Work roll of hot rolled strip tempering rack and medium plate mill rack

Tandem rolling bar and rack of high speed wire mill

Chemical Composition

Roll name | C | Si | Mn | P | S | Ni | Cr | Mo | Mg |

Ni-Cr-Mo semi-chilled cast iron centrifugal composite roll | 2.90~3.60 | 0.30~0.80 | 0.20~0.50 | ≤0.40 | ≤0.10 | 3.01~4.50 | 0.50~1.70 | 0.20~0.60 | / |

Ni-Cr-Mo infinite chilled nodular cast iron centrifugal composite roll | 2.90~3.60 | 0.60~1.00 | 0.50~1.00 | ≤0.20 | ≤0.10 | 3.01~5.00 | 1.00~2.00 | 0.20~0.60 | / |

Ni-Cr-Mo nodular cast iron centrifugal composite roll(II) | 2.90~3.60 | 1.00~2.20 | 0.40~0.70 | ≤0.10 | ≤0.10 | 2.51~3.50 | 0.10~0.60 | 0.40~1.00 | >0.04 |

Ni-Cr-Mo nodular cast iron centrifugal composite roll(III) | 2.90~3.60 | 1.00~2.20 | 0.40~0.70 | ≤0.10 | ≤0.03 | 3.51~4.50 | 0.20~0.80 | 0.40~1.00 | >0.04 |

Cr-Mo chilled nodular composite cast iron roll | 3.20~3.70 | 0.50~1.20 | 0.50~1.00 | ≤0.40 | ≤0.03 | / | 0.20~0.80 | 0.20~0.60 | >0.04 |

Ni-Cr-Mo chilled nodular composite cast iron roll | 3.20~3.70 | 0.50~1.20 | 0.50~1.00 | ≤0.40 | ≤0.03 | 0.50~1.00 | 0.20~0.80 | 0.20~0.60 | >0.04 |

Ferrite nodular composite cast iron roll | 2.90~3.60 | 1.00~2.20 | 0.50~1.00 | ≤0.10 | ≤0.03 | 1.00~3.00 | 0.10~0.60 | 0.40~1.00 | >0.04 |

Pearlite nodular composite cast iron roll | 2.90~3.60 | 1.00~2.20 | 0.50~1.00 | ≤0.10 | ≤0.03 | 2.00~3.00 | 0.10~0.60 | 0.40~1.00 | >0.04 |

Physical Properties

Roll name | Roll-body outer-layer hardness HSD | Roll-neck (spherical core) hardness HSD | Tensile strength (spherical core) Mpa |

Ni-Cr-Mo semi-chilled cast iron centrifugal composite roll | 70-85 | 35-48 | >300 |

Ni-Cr-Mo infinite chilled nodular cast iron centrifugal composite roll | 65-85 | 35-48 | >300 |

Ni-Cr-Mo nodular cast iron centrifugal composite roll(II) | 55-75 | 35-48 | >400 |

Ni-Cr-Mo nodular cast iron centrifugal composite roll(III) | 60-80 | 35-48 | >400 |

Cr-Mo chilled nodular composite cast iron roll | 58-70 | 35-48 | >300 |

Ni-Cr-Mo chilled nodular composite cast iron roll | 60-72 | 35-48 | >300 |

Ferrite nodular composite cast iron roll | 45-55 | 35-48 | >400 |

Pearlite nodular composite cast iron roll | 55-65 | 35-48 | >400 |