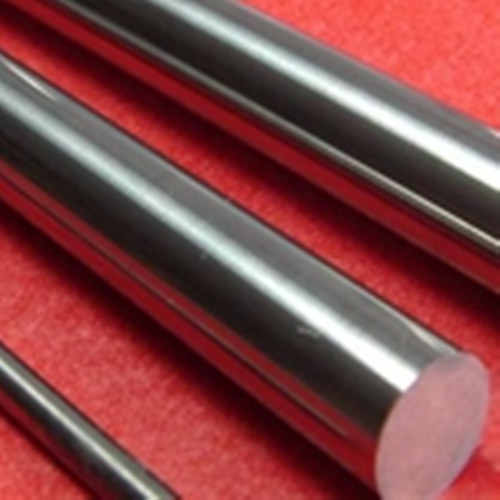

M35 DIN 1.3243 High Speed Tool Steel Round Bar

- Model

- m35,1.3243

Item specifics

- Delivery condition

- Cold drawn only

- Surface Condition

- Smooth

- Shape

- round

- Application

- drill, tools

Review

Description

Introduction of M35 Steel:

M35 high speed tool steel round bar is a conventionally manufactured cobalt alloyed high speed tool steel. The various stages of the manufacturing process are chosen and controlled so that an end product is obtained with a good structure in terms of carbide size and distribution.

Applications of M35 Steel:

M35 high speed tool steel round bar is a high speed tool steel suitable for cutting tools such as, broaches, taps, milling, reamers, hobs, shapers cutters, saws etc. In terms of performance, M35 hss bar is an all-round steel to be used in cutting conditions where demands for hot hardness are of importance. M35 high speed tool steel round bar is also suitable for cold work applications, where exacting demands are imposed on wear resistance. The steel possesses an admirable combination of wear resistance and toughness and in these respects superior to the high alloyed cold work steels.

PROPERTIES of M35 Steel:

M35 high speed tool steel round bar is medium-alloyed and has a good machinability containing Cobalt for increased hot hardness. The composition of M35 hss bar makes for a good combination of toughness and hardness. By virtue of these well balanced properties M35 hss bar has come into very wide use for cutting tools.

Characteristics of M35 Steel:

High Red Hardness

High Wear Resistance and Cutting Ability

Fine Grain Size and Carbide Particle Size

Size available of M35 Steel:

Round Bar: Dia2mm-Dia200mm

Flat: thickness, width, contracted.

All Grades Comparison of M35 Steel:

AISI | DIN | B.S. | JIS |

M35 hss bar | 1.3243 | BM35 hss bar | SKH55 |

Chemical Composition(%) of M35 Steel:

C | Si | Mn | P | S | Cr | Mo | V | W | Co |

0.88-0.95 | 0.40 max | 0.40 max | 0.030 max | 0.030 max | 3.80-4.50 | 4.75-5.20 | 1.75-1.90 | 6.00-6.70 | 4.60-5.00 |

METHODS OF MAKING TOOLS:

M35 high speed tool steel round bar can be worked in the same way as other high speed tool steel by plastic forming, machining, grinding, electrical discharge machining, welding and polishing. M35 hss bar is amenable to cold forming. In grinding, local heating of the surface, which might alter the temper, must be avoided. Grinding wheel makers can furnish advice on the choice of grinding wheels. Machining is carried out using carbide or high speed steel tools.

Final Grinding:

Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure the grinding wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a copious supply of coolant. If dry grinding is resorted to then use a very soft wheel.

HEAT TREATMENT:

Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each M35 high speed tool steel round bar steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of high speed tool steel.

l Forging: Pre heat the M35 high speed tool steel round bar high speed steel slowly and uniformly to 450-500°C and equalise. Then increase more quickly to the forging temperature of 950-1100°C and equalise prior to forging. Do not allow the forging temperature to drop below 950°C, if this occurs re heating will be necessary. Always cool the steel very slowly after forging.

l Annealing: M35 high speed tool steel round bar is supplied in the annealed and machineable condition. Re annealing will only be necessary if the steel has been hot worked, forged, or hardened by the toolmaker. Heat the M35 hss bar high speed steel to 850°C at a rate of no more than 220°C per hour. Always hold at temperature for one hour per 25mm of thickness (with two hours being minimum). Furnace cool slowly. The M35 hss bar annealed hardness achieved should be 260 Brinell or lower.

l Stress Relieving: If tools produced from M35 hss bar high speed steel are heavily machined or ground it is recommended to stress relieve after machining and prior to hardening to minimise the possibility of distortion. To stress relieve heat the component to 600-700°C and soak well (approx 2 hours) Cool slowly in the furnace. The tools can be finish machined before heat treatment.

l Hardening: For best results harden in a vacuum or controlled furnace, or in a properly rectified salt bath. Pre heat thoroughly in two steps to 450-500°C, then to 820-870°C, transfer to the high temperature salt bath or furnace. The exact hardening temperature to use for M35 hss bar will depend on the type of work being treated, but in general components should be hardened from the range of 1050-1250°C.

l Tempering: M35 high speed steel components can be tempered between 510-620°C. Triple tempering is recommended with a minimum of two hours at temperature per cycle. The component should be cooled in still air to room temperature between tempering treatments.

Temperature [°C] 540 560 580

Hardness [HRc] 67 66 65

Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.