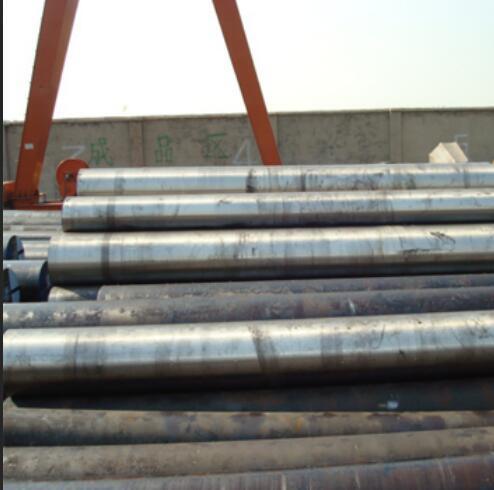

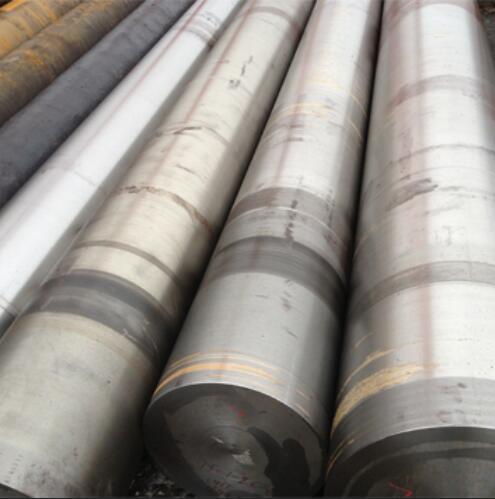

DIN 1.6587 18CrNiMo7-6 Case Hardening Steel Bar

- Model

- 1.6587 18CrNiMo7-6

Item specifics

- Diameter

- 50-550mm

- Delivery condition

- Hot forged, Hot rolled, QT

- Surfac condition

- Black

Review

Description

Application of 1.6587 steel:

Severely stressed components for mechanical engineering and automobile industry, gear for mining, cement plants, power plants, mobile cranes and earth-moving equipment, paper mill, sugar mill, marine, wind gear, railway systems, oil platform, etc.

Quality Standard of 1.6587 steel:

EN 10084 Case hardening steels

Chemical Composition of 1.6587 steel (%)

C | Mn | Si | P | S | Cr | Ni | Mo |

0.15-0.21 | 0.50-0.90 | 0.40 max | 0.025 max | 0.025 max | 1.50-1.80 | 1.40-1.70 | 0.25-0.35 |

Mechanical Properties of 1.6587 steel: (T=20°C if not differently stated)

Process | Diameter(mm) | Tensile Strength Rm (Mpa) | Yield Strength Rp0.2 (Mpa) | Elongation A5 (%) | Area Reduction Ratio C (%) | Impact Value Kv (J) Room Temperature | Hardness (HB) |

SOFT ANNEALED | / | / | / | / | / | / | 229 max |

NORMALIZED | / | / | / | / | / | / | 140-210 |

QUENCHED AND TEMPERED | 11 max | 1180-1420 | 835 min | 7 min | 30 min | 44 min | 354-406 |

QUENCHED AND TEMPERED | 43829 | 1080-1320 | 785 min | 8 min | 35 min | 44 min | 327-384 |

QUENCHED AND TEMPERED | 31-63 | 980-1270 | 685 min | 8 min | 35 min | / | 295-373 |

QUENCHED AND TEMPERED | 100-160 | 1000-1200 | 800 min | 11 min | 50 min | 45 min | 295-353 |

QUENCHED AND TEMPERED | 160-250 | 1000-1200 | 800 min | 11 min | 50 min | 45 min | 295-353 |

Heat treatment of 1.6587 steel:

Soft Annealing: Heat 17CrNiMo6 to 650-700℃, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

Normalizing: 850-880℃, air.

Hardening: Carburising: 880-980oC. Core Hardening: 830-870℃, water. Case Hardening: 780-820℃, water.

Tempering: Temperature: 150-200℃

Forging: Hot forming temperature: 1100-900℃.