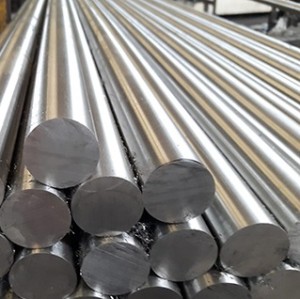

2205 1.4462 Duplex Stainless Steel Bar

- Model

- 1.4462 , 2205

Item specifics

- Diameter range

- 50-260mm

- Tolerance range

- h8, h9

- Delivery condition

- Solution treatment

- Surface Condition

- Bright

Review

- G***h

- 2020/11/28 12:16

Hi, here on the forum guys advised a cool Dating site, be sure to register - you will not REGRET it [url=https://bit.ly/39cc9gy]https://bit.ly/39cc9gy[/url]

Description

1.4462, F55, 2205 duplex stainless steel is a 22% Chromium, 3% Molybdenum, 5-6% Nickel nitrogen alloyed duplex stainless steel with high general, localized and stress corrosion resistance properties in addition to high strength and excellent impact toughness. Duplex stainless steel provides pitting and crevice corrosion resistance superior to austenitic stainless steels in almost all corrosive media. It also has high corrosion and erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic.

Applications of 2205 stainless:

l Chemical processing, transport and storage – pressure vessels, tanks, piping, and heat exchangers

l Oil and gas exploration and processing equipment – piping, tubing, and heat exchangers

l Marine and other high chloride environments

l Effluent scrubbing systems

l Pulp and paper industry – digesters, bleaching equipment, and stock-handling systems

l Cargo tanks for ships and trucks

l Food processing equipment

l Biofuels plants

Chemical Composition(%) of 2205 steel:

Steel Grade |

C |

Si | Mn | P | S | Cr | Ni | Mo | N |

2205 |

0.03 max |

1.0 max | 2.0 max | 0.030 max | 0.020 max | 22.0-23.0 | 4.50-6.50 | 3.0-3.5 | 0.14-0.20 |

1.4462 |

0.03 max |

1.0 max | 2.0 max | 0.035 max | 0.015 max | 21.0-23.0 | 4.50-6.50 | 2.50-5.50 | 0.10-0.22 |

Mechanical Properties (Annealed) of 2205 duplex:

|

Hardness (HB) |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) (Long.) |

Impact Value (J) (Long.) |

|

270 max |

650-880 |

450 min |

25 min |

100 min |