420 1.4021 SUS420J1 Stainless Steel Bar

- Model

- AISI 420

Item specifics

- Delivery condition

- annealed

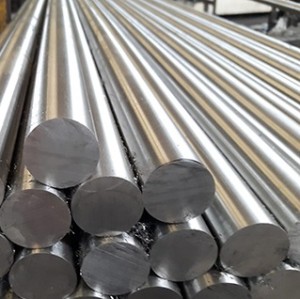

- Surface condition

- Black, Machined

- Similar grades

- AISI 420 2Cr13 S42020

- Standard

- ASTM A276

Review

Description

Introduction AISI 420

AISI 420 Stainless Tool Steel is a martensitic stainless steel with 12% Chromium which is sufficient to give good corrosive resistance properties. It’s best corrosive resistance is when hardened and surface is ground or polished.It has good ductility in the annealed condition but can be hardened up to 500HB (highest of the chromium grades). Martensitic Grades are known for high hardness and allowances must be made for poor weldability and usually allowances for a final harden and temper treatment. Steel is magnetic and welding is not recommended.

AISI 420 Applications

Moulds for corrosive plastic materials such as PVC, recycled polymers etc., moulds for chemically aggressive plastics and plastics containing abrasive fillers, mould inserts, dies and gauges for PVC extrusions, screws and barrels for extruders, moulds for automotive, food, medical and optical industry such as spectacles, compact discs, lenses.

AISI 420 Chemical Composition(%)

C | Si | Mn | P | S | Cr | Ni | Mo |

0.15 min | 1.0 max | 1.0 max | 0.040 max | 0.030 max | 12.0-14.0 | 0.75 max | 0.50 max |

AISI 420 Mechanical Properties (Q+T)

Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) | Hardness (HB) |

850-1000 | 600 min | 12 min | 280 min |

AISI 420 Heat Treatment

Annealing:

For maximum softness, heat uniformly to 1500 – 1650°F (816 – 899°C) and cool slowly in the furnace.

Stress Relieving:

Heat at 300 – 800°F (149 – 427°C) for 1 to 3 hours, cool in air or quench in oil or water.

Hardening:

Preheat, then heat to 1800 -1950°F (982 – 1066°C), soak at temperature and air cool or quench in warm oil.