H13 1.2344 SKD61 PESR Hot Forged Ultrafine Hot Work Tool Steel Round Bar For Die Casting Mould

- Price

- US $2000

- Model

- H13 / 1.2344 / SKD61

- MOQ

- 1 metric ton

Item specifics

- Round Diameter Range

- 80-1000mm

- Standard

- AISI, ASTM, BS, DIN, GB, JIS

- Process

- PESR

- Delivery

- Annealed

- Surface

- grinded, or turned bright

- UT test standard

- SEP1921-84 class3 C/c or D/d

Review

Description

Applications

Chemical Composition

Steel Grade | C | Si | Mn | P | S | Cr | Mo | V |

H13 | 0.32-0.45 | 0.90-1.25 | 0.20-0.60 | 0.030 max | 0.030 max | 4.75-5.50 | 1.10-1.75 | 0.80-1.25 |

DIN1.2344 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.030 max | 4.80-5.50 | 1.20-1.50 | 0.80-1.15 |

SKD61 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.020 max | 4.80-5.50 | 1.00-1.50 | 0.80-1.15 |

Equivalent grades

AS 1239 | ASTM A 681 | BS 4659 | BS EN ISO 4957 | JIS G 4404 | Werkstoff |

H13A | H13/UNS T20813 | BH13 | X40CrMoV 5-1 | SKD 61 | 1.2344/X40CrMoV5-1 |

High level of toughness and ductility

Good resistance to abrasion at both low and high temperatures

Good high-temperature strength

High through-hardening properties

Very limited distortion during hardening

Good resistance to thermal fatigue

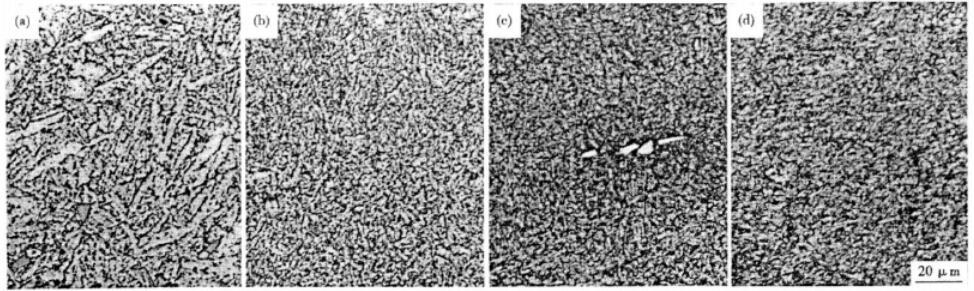

Ultrafine Treatment

The steel's microstructure is effectively refined by the multiple cycle heating and quenching method. The specific process is to heat the steel from room temperature to a temperature slightly above Ac3, hold it for a short time at a lower austenitizing temperature, then quickly quench and cool it to room temperature, and repeat the process. Each cycle heating will obtain more fine austenitic grains.