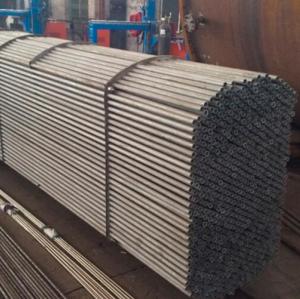

TP347h Stainless Steel Pipe Seamless And Welded sa213 a312

- Model

- Tp347h Stainless Steel Pipe

Item specifics

- Delivery condition

- Cold Drawn, Polished, Bright Annealed, Annealed an

- Pipe End Finish

- Beveled End, Plain End, Treaded

Review

Description

Tp347h Stainless Steel Pipe Seamless And Welded

tp347h stainless steel pipe is a brand of stainless steel manufactured according to the ASTM standard. tp347h stainless steel pipe s are equivalent to china 0Cr18Ni11Nb stainless steel pipe. TP347H (1Cr19Ni11Nb) is a high-carbon niobium-containing Cr-Ni austenitic stainless steel. Due to the stabilizing element Nb, it has good resistance to intergranular corrosion and polysulfuric acid intergranular stress corrosion.

A312 TP347H Stainless Steel Pipe Composition Table

AISI | Ni | Mn | Si | S | C | Cr | P | Mo | N | |

TP 347H | min. | 9.0 | – | – | – | 00.04 | 17.0 | – | 3.00 | – |

max. | 13.0 | 2.0 | 1.00 | 00.030 | 00.10 | 19.0 | 00.045 | 4.00 | – | |

ASTM A312 TP347H Pipe Material Equivalent

MATERIAL | UNS | WERKSTOFF NR. |

| USA | GERMAN |

TP347H | S34709 | 1.4961 |

ASTM A312 TP47H Specification Chart

ASTM / ASME Name | ASTM A312 / ASTM SA312 |

ANSI / ASME Standard | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

Pipe End Finish | Beveled End, Plain End, Treaded |

Delivery Condition | Cold Drawn, Polished, Bright Annealed, Annealed and Pickled |

Pipe Wall Thickness | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

Industrial Value Added Services | Export Packaging, Threading, Threading, Non Beveling, Customer Tagging/ Marking, Destructive, Grooving, Export Documentation, Ultrasonic Testing, Machining, Cutting, Destructive, MTR’s Available, Material testing, Color Coding, Polishing |

Marking on AISI 347H Pipes | Specification Grade Nominal Pipe Sizes Pipe Schedule or Wall Thickness Manufacturing Method (Seamless / Welded) Heat Number Manufacturer’s Name or Custom Logo - on request Marked Pipe Sample: ANSI B36.19 ASTM A312 TP347H 12" NB SCH 40S SEAMLESS HEAT NO. XXXX |

ASTM A312 TP347H Stainless Steel Pipe Mechanical

Property | Value | Temperature | Comment |

Elastic modulus | 195 GPa | 23.0 °C | Typical for Austenitic Stainless Steel |

Elongation A50 | 25 - 35 % | 23.0 °C | |

Poisson's ratio | 0.3 [-] | 23.0 °C | Typical for Austenitic Stainless Steel |

Shear modulus | 77 GPa | 23.0 °C | Typical for Austenitic Stainless Steel |

Tensile strength | 515 MPa | 23.0 °C | |

Yield strength | 205 MPa | 23.0 °C | |

TP347H Stainless Steel Pipe Thermal

Property | Value | Temperature | Comment |

Coefficient of thermal expansion | 1.7E-5 - 1.9E-5 1/K | 23.0 °C | Typical for Austenitic Stainless Steel |

Melting point | 1230 - 1480 °C | | Typical for Austenitic Stainless Steel |

Specific heat capacity | 440 J/(kg·K) | 23.0 °C | Typical for Austenitic Stainless Steel |

Thermal conductivity | 11 - 21 W/(m·K) | 23.0 °C | Typical for Austenitic Stainless Steel |

Typical Elevated Temperature Tensile Properties stainless 347 (0.060 inch thick / 1.54 mm thick)

Test Temperature | Yield Strength | Ultimate Tensile Strength | % Elongation | |

°F | °C | |||

68 | 20 | 36,500 | 93,250 | 45.0 |

400 | 204 | 36,600 | 73,570 | 36.0 |

800 | 427 | 29,680 | 69,500 | 30.0 |

1000 | 538 | 27,400 | 63,510 | 27.0 |

1200 | 649 | 24,475 | 52,300 | 26.0 |

1350 | 732 | 22,800 | 39,280 | 40.0 |

1500 | 816 | 18,600 | 26,400 | 50.0 |

Why 347h SS is used for Chemical Processing?

The grade 347 is specific austenitic stainless steel made for repeated intermittent exposure to temperatures above 800 degrees Celsius. These are modifications of 304 stainless steel. They are similar to the 321 grade in some mechanical properties but different in that it has columbium in the composition. The material is corrosion resistant to most corrosive media in medium to high temperatures. This is an important aspect required at chemical processing. The material has minimum yield strength of 205MPa and the minimum tensile strength at 515MPa. This allows the material to withstand high pressure at temperatures above 850 degrees Celsius. The pipes and components also have a good elongation and high hardness. The 304 material can undergo intergranular corrosion above temperatures 850 F. The 347H has a higher carbon content and heat resistant so that it can perform in this temperature range. The combination of the pressure containment capacities, the strength, hardness, heat resistance and corrosion resistance make it applicable for chemical processing. These properties also make the material used in other high corrosive, high heat applications such as the boiler tubes and casings, radiant super heaters, heat exchanger tubes, oil and gas refineries and aircraft exhaust stacks.

TP347H Stainless Steel Pipe Creep and Stress Rupture Properties

Typical creep and stress rupture data for Alloys 321 and 347 stainless steel are shown in the figures below. The elevated temperature creep and stress rupture strengths of the stabilized steels are higher than those of unstabilized Alloys 304 and 304L. These superior properties for the 321 and 347 alloys permit design of pressure-containing components for elevated temperature service to higher stress levels as recognized in the ASME Boiler and Pressure Vessel Code.

TP347H Stainless Steel Pipe Marking of packages

Through a correct and complete marking of packaging will create the conditions to avoid misuse, accidents, wrong delivery, mass and volume losses and customs penalties. We do marking very clear and precise on ASTM A213 TP347H Stainless Steel Seamless Tubes. You should contrast clearly with the package, usually it is applied in black color.