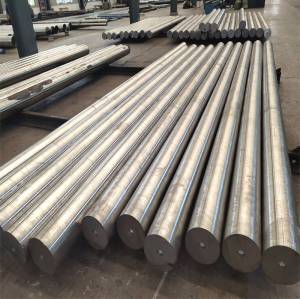

2750 1.4410 Stainless Steel Bar

- Model

- 2750 1.4410

Item specifics

- Diameter

- 10-300mm

- Surface condition

- Black, Blasted,

- Delivery Condition

- Annealed, Hot rolled+annealed, Cold drawn only

Review

Description

2750 S32750 1.4410 Duplex Stainless Steel

UNS S32750 is a super duplex stainless steel supplied in the solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitrogen contents result in a Pitting Resistance Equivalent number (PREN) of >41, providing pitting and crevice corrosion resistance superior to austenitic and duplex stainless steels in almost all corrosive media, and a Critical Pitting Temperature exceeding 50°C.

Benefits

l Very high corrosion resistance

l Superior resistance to pitting and cracking in harsh environments

l Good weldability and workability

l High yield and tensile strength

Equivalent grades

| DIN | EU | USA | France | Sweden |

|---|---|---|---|---|

| EN | - | AFNOR | SS | |

| 1.441 | X2CrNiMoN25-7-4 | S32750 | Z3CND25-06Az | 2328 |

Chemical composition %

| C | Si | Mn | Ni | P | S | Cr | Mo | N |

|---|---|---|---|---|---|---|---|---|

| max 0.03 | max 1 | max 2 | 44355 | max 0.035 | max 0.015 | 24 - 26 | 3 - 4.5 | 0.24 - 0.35 |

MECHANICAL PROPERTIES

Yield strength Rp0.2, | Tensile strength Rm, | Elongation | Hardness | Impact, Charpy-V, -46ºC | Pre |

|---|---|---|---|---|---|

≥ 550 | ≥ 750 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 | ≥ 40 |

Synopsis

UNS S32750 or 2507 Duplex is a super austenitic premium stainless that is similar to 2205 Duplex. 2507 Stainless Steel is composed of 25% Chrome and 7% nickel which causes the alloy to have an even higher corrosion resistance and longer life span. Along with it being corrosion resistant, UNS S32750 has a high resistance of cracking and pitting, and the yield and tensile strength make it comparable to nickel alloys.

Resistance

Large chromium levels as well as molybdenum content of 2507 Duplex makes this material very resistant to corrosive acidic elements. It implements great resistance to chloride SCC and is preferable to 2205 Duplex in both strength and corrosive resistance.

Processing

2507 Duplex material will be heat treated at climates ~2000°F. After heated, the substance will be pursued by a annealed solution at ~1900°F then submergence in water. 2507 is easily cold worked and has a greater strength/lower ductility than austenitic stainless grades.