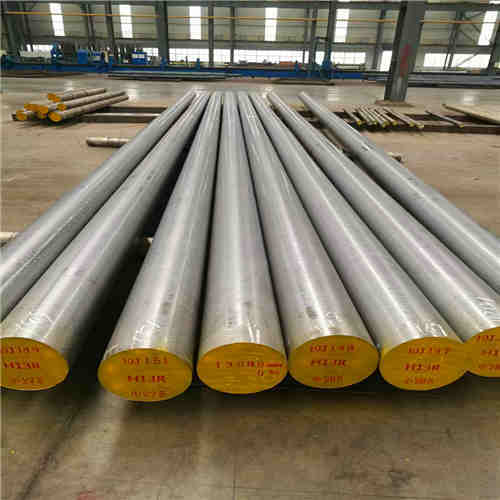

20CrNiMoA Hot Forged Alloy Steel Round Bar

- Model

- 20CrNiMoA

Item specifics

- Delivery Condition

- +QT or annealed

- Surface Condition

- black or grounded or peeled

Review

Description

20CrNiMoA Alloy Steel

Supplying Size:

Rolled: Diameter 40-200mm

Forged: Diameter 80-600mm

Equivalent

USA | Germany | China | Japan | France | England | ISO |

|---|---|---|---|---|---|---|

ASTM/AISI/UNS/SAE | DIN,WNr | GB | GB | AFNOR | BS | ISO |

8620 / G86200 | 21NiCrMo2/ 1.6523 | 20CrNiMo | SNCM220 | 20NCD2 | 805M20 | 20NiCrMo2 |

Chemical composition

C | 0.17~0.23 | Si | 0.17~0.37 | Mn | 0.60~0.95 | P | ≤0.035 |

|---|---|---|---|---|---|---|---|

S | ≤0.035 | Cr | 0.40~0.70 | Mo | 0.20~0.30 | Ni | 0.35~0.75 |

Mechanical Properties

The mechanical properties of annealed GB 20CrNiMoA alloy steel are outlined in the table below

Tensile | Yield | Bulk modulus | Shear modulus | Poisson’s ratio | Izod Impact |

|---|---|---|---|---|---|

KSI | KSI | KSI | KSI | ft.lb | |

76900 | 55800 | 20300 | 11600 | 0.27-0.30 | 84.8 |

Heat treatment Related

Annealing of 20CrNiMoA Alloy structural steel

Slowly heated to 850c and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. The 20CrNiMoA alloy steel will get MAX 250 HB (Brinell hardness).

Hardening of 20CrNiMoA Alloy structural steel

Heated slowly to 880-920c, Then after adequate soaking at this temperature quench in oil. Temper as soon as tools reach room temperature.

GB 20CrNiMoA

alloy Steel is a high quality Quenched and Tempered Alloy Structural steel, and it belong to the high quality low carbon, low chromium, molybdenum, nickel case hardening steel. Oil Quenched & Tempered Hardness is 28-34 HRC. GB 20CrNiMoA steel Annealing delivery hardness less than 250HB.

GB 20CrNiMoA

Alloy structural steel properties is a Nickel chromium molybdenum alloy steel specification. 20CrNiMoA With a lower carbon content range, So GB 20CrNiMoA steel have good weldability.

Applications

GB 20CrNiMoA steel is widely used for a variety of applications in the used in the automotive and engineering industries for toolholders and other such components. Typical applications such as valve bodies, pumps and fittings, Shaft, the high load of wheel, bolts, double-headed bolts, gears, etc