JIS G3472 Electric Resistance Welded Carbon Steel Tubes for Automobile

- Model

- JIS G3472

Item specifics

- Delivery condition

- +A or +N

- Surface condition

- smooth

Review

Description

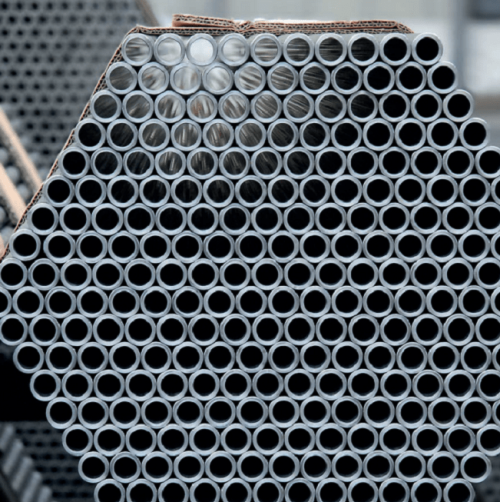

JIS G3472 Electric Resistance Welded Carbon Steel Tubes for Automobile

G3472 Welded Steel Tubes manufacture

The tubes shall be manufactured from hot finished welded tubes by cold drawing. Other suitable methods of cold working are permitted. The tubes shall be delivered in the delivery condition +N which means that after the final cold drawing operation the tubes are normalized in a controlled atmosphere.All non-destructive testing (NDT) activities shall be carried out by qualified and competent level 1, 2 and/or 3 personnel authorised to operate.

Benefits Of G3472 Welded Steel Tubes

Higher Strength & Hardness Properties

Size Accuracy

Enhanced Appearance

Uniform Micro-structure

Easier To Machine

Superior Finish In Subsequent Manipulations

G3472 welded Steel Tubes Applications

1.Hydraulic Cylinders

2.Auto and Truck Axles

3.Suspension parts and shock absorbers

4.High Speed Shafts and rollers

5.Bearings and Spacers

6.Roll cages

7.Agricultural components and many other machined tubular parts.

G3472 welded Steel Tubes Sizes and tolerances

Specified outside diameter with tolerance: 4 (+/-0,08) to 300 (+/-0,35) mm

Specified inside diameter with tolerance: 2 (+/-0,15) to 100 (+/-0,35) mm

Lengths: standard length of 6 m ; exact length ; other length

Straightness: The deviation from straightness of any tube length L shall not exceed 0,0015 L. Deviations from straightness over any one metre length shall not exceed 3 mm.

Standards

JIS G3472 Electric Resistance Welded Carbon Steel Tubes for Automobile

G3472 welded Steel Tubes Chemical Component

Symbol of grade | C | Si | Mn | P | S |

STAM290GA | 0.12 max. | 0.35 max. | 0.60 max. | 0.035 max. | 0.035 max. |

STAM290GB | 0.12 max. | 0.35 max. | 0.60 max. | 0.035 max. | 0.035 max. |

STAM340G | 0.20 max. | 0.35 max. | 0.60 max. | 0.035 max. | 0.035 max. |

STAM390G | 0.25 max. | 0.35 max. | 0.30 to 0.90 | 0.035 max. | 0.035 max. |

STAM440G | 0.25 max. | 0.35 max. | 0.30 to 0.90 | 0.035 max. | 0.035 max. |

STAM440H | 0.25 max. | 0.35 max. | 0.30 to 0.90 | 0.035 max. | 0.035 max. |

STAM470G | 0.25 max. | 0.35 max. | 0.30 to 0.90 | 0.035 max. | 0.035 max. |

STAM470H | 0.25 max. | 0.35 max. | 0.30 to 0.90 | 0.035 max. | 0.035 max. |

STAM500G | 0.30 max. | 0.35 max. | 0.30 to 1.00 | 0.035 max. | 0.035 max. |

STAM500H | 0.30 max. | 0.35 max. | 0.30 to 1.00 | 0.035 max. | 0.035 max. |

STAM540H | 0.30 max. | 0.35 max. | 0.30 to 1.00 | 0.035 max. | 0.035 max. |

G3472 Welded Steel Tubes Appearance

The internal and external surface finish of the tubes shall be typical of the manufacturing process and the heat treatment, and it shall be such that any surface imperfections such as ridges, dents or shallow grooves requiring dressing can be identified. It shall be permissible to dress, by grinding or machining, surface imperfections provided that, after doing so, the dimensions are within the specified tolerances. All dressed areas shall blend smoothly into the contour of the tube. Surface imperfections which encroach on the specified minimum wall thickness shall be considered defects and tubes containing these shall be deemed not to conform to this part of EN 10305.The tubes shall have smooth outer and inner surfaces with a roughness Ra 4 um, unless a reduced roughness of Ra 2 um is specified for the inner surface is specified.

Preparation of ends

The tubes shall be delivered with square cut ends. The ends shall be free from excessive burrs.

G3472 Welded Steel Tubes Inspection

Chemical analysis

Tensile test

Flattening test

Drift expanding test

Dimensional inspection

Visual examination

NDT for verification of leak tightness

G3472 Welded Steel Tubes Protection

The tubes shall be delivered with a temporary protection against corrosion.

The tubes shall be phosphatized before temporary protection.

The tube ends shall be protected with plugs or caps.

G3472 Welded Steel Tubes Option

1:reduced internal roughness of 2 um

2:lengths other than 6 m

3: alternative marking

4: protection by phosphatization

5:protection by galvanization and chromatization type blue-white

6:protection by galvanization and chromatization type yellow

7:protection by galvanization and chromatization type olive green

8:protection of tube ends

9:special packaging

Other Services

1 Cutting: Small pieces

2 End: Plaint or Beveled or threaded

3 CNC Machine: Produce as your drawing

4 Package: Bare/Nylon/Canvas/Wooden

5 Payment:T/T, L/C, O/A(request credit)

6 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)