JIS G3429 Seamless steel tubes for high pressure gas cylinders

- Model

- JIS G3429

Item specifics

- Delivery condition

- +A or +N

- Surface condition

- polished or honed

Review

Description

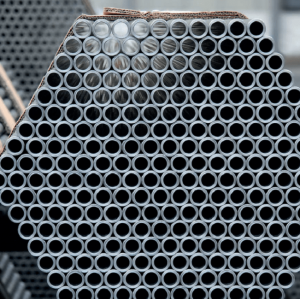

JIS G3429 Seamless steel tubes for high pressure gas cylinders

Dimensions and dimensional tolerances

Dimensions

outside diameter: 40-500mm

wall thickness: 3-30mm

Dimensional tolerances

Tolerance on outside diameter :+/- 1%

Tolerance on wall thickness : +30 / -0%

Tolerance on eccentricity : 20 max %

Tolerance on length : +30 / -0 mm

Our advantage :

1. High Quality, Reasonable Price

2. Over 40 Years Experience

3. ISO NQA Certificated Factory

4. Worldwide shipping

5. Emergency Orders and Fast Delivery

Manufacturing method

The manufacturing method shall be as follows.

a) Tubes shall be manufactured by combination of the tube manufacturing method and the finishing method which are indicated. The symbol of manufacturing method shall be in accordance.

b) Tubes shall normally be as manufactured without heat treatment.

c) Tubes shall be furnished with plane ends, unless otherwise specified.

Chemical composition

Symbol of grade | C | Si | Mn | P | s | Ni | Cr | Mo |

STH11 | 0.50 max. | 0.10 to 0.35 | 1.80 max. | 0.035 max. | 0.035 max. | / | / | / |

STH12 | 0.30 to 0.41 | 0.10 to 0.35 | 1.35 to 1.70 | 0.030 max. | 0.030 max. | / | / | / |

STH21 | 0.25 to 0.35 | 0.15 to 0.35 | 0.40 to 0.90 | 0.030 max. | 0.030 max. | 0.25 max | 0.80 to 1.2 | 0.15 to 0.3 |

STH22 | 0.33 to 0.80 | 0.15 to 0.35 | 0.40 to 0.90 | 0.030 max. | 0.030 max. | 0.25 max | 0.80 to 1.2 | 0.15 to 0.3 |

STH31 | 0.35 to 0.40 | 0.10 to 0.50 | 1.20 to 1.50 | 0.030 max. | 0.030 max. | 0.50 to 1.00 | 0.30 to 0.60 | 0.15 to 0.25 |

Appearance

Appearance shall be as follows.

a) Tubes shall be straight and shall have cut-ends square to the tube axis for practical purposes.

b) Both the internal and external surfaces of tubes shall be smoothly finished and free from defects detrimental to use.

c) The tubes may be repaired by grinding, machining or other method, provided that the wall thickness of the product after repair shall be within the range of wall thickness tolerance. However, repair by welding shall not be performed.

d) The surface of the repaired part shall be smooth along the contour of the tube.

Tests

Chemical analysis

Hydrostatic test and non-destructive test

Optional tests