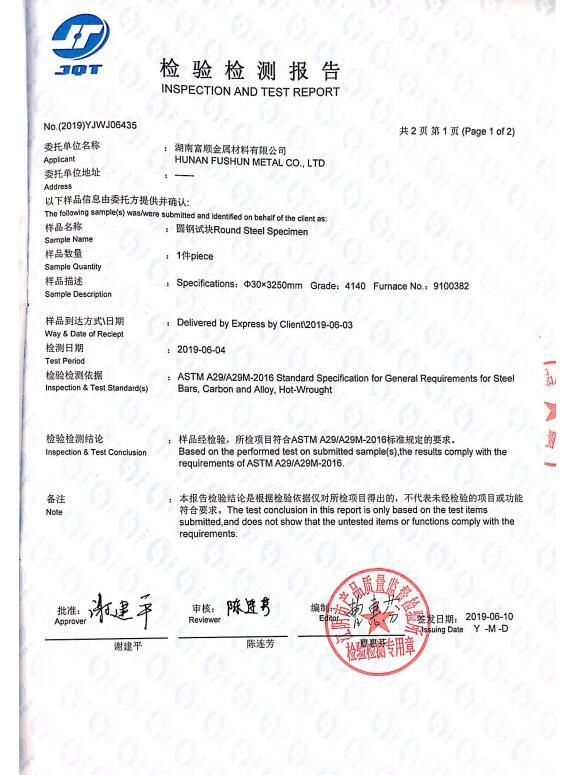

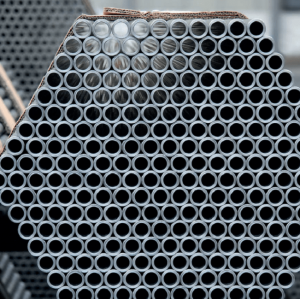

AISI 4140 G41400 SCM440 42CrMo4 1.7225 Alloy Steel Seamless Round Tube

- Model

- 4140 G41400 SCM440 42CrMo4 1.7225

Item specifics

- OD

- 40-400MM

- WT

- 5-30MM

- Delivery condition

- QT

- Surface condition

- peeled

Review

Description

4140 Seamless Tubing Are The Low Alloy Materials Used In The Industries. It Consists Of Manganese, Molybdenum And Chromium Chemical Components Which Adds Advanced Properties And Characteristics To AISI 4140 Material. Hence, Making It More Applicable For The Applications As Compared To Other Materials.The Molybdenum Chemical Component Used To Enhance The Resistivity Of The Material In High Elevated Temperatures.

Applications

Superior tensile strength and toughness

High strength to weight ratio

Easily heat treatable to a broad range of strength, machinability, and hardness.

Applications: aircraft components, hydraulic cylinders, rollers, structural apps, truck and automotive parts.

Chemical Composition (%)

Steel (UNS) | C | Si | Mn | P (≤) | S (≤) | Cr | Mo |

4140 (G41400) | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.040 | 0.80-1.10 | 0.15-0.25 |

Steel | Tensile strength (Mpa) | Yield strength (Mpa) | Elongation in 50 mm, % | Reduction in area, % | Hardness (HB) | Sample diameter | Conditions |

AISI 4140 | 1020 | 655 | 17.7 | 46.8 | 302 | 25.4mm (1 inch) | Normalized at 870 °C |

655 | 414 | 25.7 | 56.9 | 197 | Annealed at 815 °C | ||

1075 | 986 | 15.5 | 56.9 | 311 | Water quenched from 845 °C & tempered at 540 °C |

Heat Treatment

AISI 4140 has enough carbon present to allow for adequate heat treatment. Recommended hardening procedures are to bring the steel up to 1,675 degrees Fahrenheit for normalization (removal of stress within the steel). After it cools properly, heat the steel to 1,550 degrees Fahrenheit before quenching it in oil. The toughness of the steel makes machining in its hardened form difficult. However, after annealing the steel at 1,600 degrees followed by a slow cooling, the steel is much softer and far easier to machine. It can then be heat-treated after machining to produce a hard, precise item.