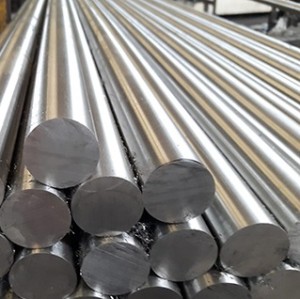

EN DIN BS 1.4501 X2CrNiMoCuWN25-7-4 Bright Duplex Stainless Steel Round Bar

- Model

- 1.4501

Item specifics

- Surface condition

- Black, Blasted, Turned, Polished

Review

Description

1.4501 X2CrNiMoCuWN25-7-4 Austenitic-ferritic Stainless Steel

Introduce

The 1.4501 is an austenitic-ferritic, high-alloy, low-carbon chromium nickel molybdenum tungsten (super duplex) steel that is resistant to chloride-containing media and can be used in areas where traditional duplex steels are no longer adequate. Due to higher contents of chromium and molybdenum in combination with tungsten, the PREN-values of the material are from 40 to> 46 J with good impact values and wear resistance properties at -40 ° C. The steel 1.4501 - ASTM A182 F55 - Superduplex: UNS S32760 is resistant to seawater, has a high resistance to surface, as well as hole and crevice corrosion and is suitable to use in sulfuric acid.

Our supply size:

Diameter : 80 to 600 mm ;

Length : 1000 to 9000 mm ;

Our advantage:

1. High Quality, Reasonable Price

2. Over 40 Years Experience

3. ISO NQA Certificated Factory

4. Worldwide shipping

5. Emergency Orders and Fast Delivery

Standard:

EN 10088-1: 2005 Stainless steels. List of stainless steels

Equivalent grades of steel X2CrNiMoCuWN25-7-4 (1.4501)

EU | USA |

X2CrNiMoCuWN25-7-4 | S32750 |

1.4501 | S32760 |

Chemical composition % of steel X2CrNiMoCuWN25-7-4 (1.4501): EN 10088-2-2005

C | Si | Mn | Ni | P | S |

max 0.03 | max 1 | max 1 | 6-8 | max 0.035 | max 0.015 |

Cr | Mo | W | N | Cu |

|

24 - 26 | 3-4 | 0.5 - 1 | 0.2 - 0.3 | 0.5 - 1 |

|

Mechanical properties of steel X2CrNiMoCuWN25-7-4 (1.4501)

Rm - Tensile strength (MPa) (+A) | 730-930 |

Rm - Tensile strength (MPa) (+AT) | 800-1000 |

Rp0.2 0.2% proof strength (MPa) (+A) | 530 |

Rp0.2 0.2% proof strength (MPa) (+AT) | 550 |

A - Min. elongation at fracture (%) (+A) | 25 |

A - Min. elongation at fracture (%) longitud., (+AT) | 20 |

Brinell hardness (HB): (+A) | 290 |

Brinell hardness (HB): (+AT) | 310 |

Application

Super Duplex steels also find applications in the chemical, paper, cryogenic and power industries for parts and subassemblies such as pumps, shafts, bushes, aerial constructions, heat exchangers, coolers, chemical transport pipelines, special tanks, valves, snd screws. The Super Duplex steels described above are subject to hyperquenching at temperatures between 1020 and 1100 ℃.

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Surface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Mill test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.