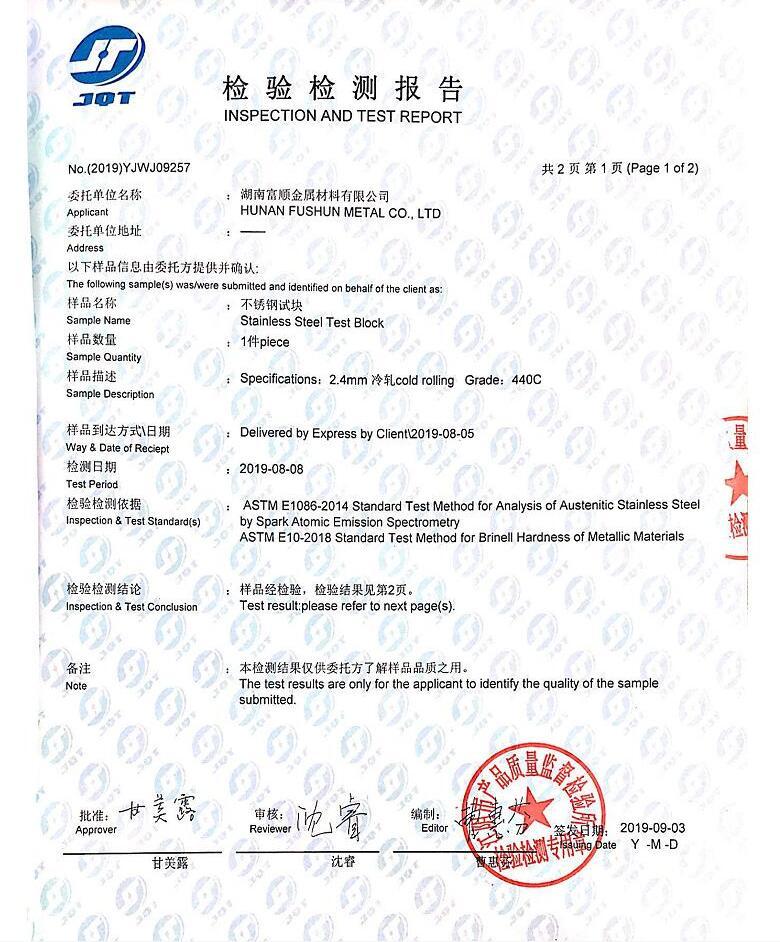

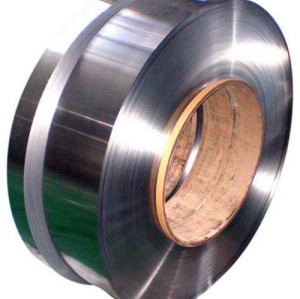

SUS440C 440C S44004 1.4125 X105CrMo17 Stainless Steel Strip Coils

- Model

- SUS440C 440C S44004 1.4125 X105CrMo17

Item specifics

- Surface Condition

- Black, Smooth, Bright

- Delivery condition

- Annealed, Cold rolled only

Review

Description

Introduce

Grade 440C is capable of attaining, after heat treatment, the highest strength, hardness and wear resistance of all the stainless alloys. Its very high carbon content is responsible for these characteristics, which make 440C particularly suited to such applications as ball bearings and valve parts.

Martensitic stainless steels are optimised for high hardness, and other properties are to some degree compromised. Fabrication must be by methods that allow for poor weldability and usually also allow for a final harden and temper heat treatment. Corrosion resistance is lower than the common austenitic grades, and their useful operating temperature range is limited by their loss of ductility at sub-zero temperatures and loss of strength by over-tempering at elevated temperatures.

Chemical Composition(%):

Product Details

Supply Range for 440C Stainless Steel

440C steel round bar: diameter 1mm~400mm

440C stainless plate: 0.1-100 thickness x 500-2000mm width x 1000-6000mm length

Other steel shape, like 440c steel sheet, 440C coil, flat bar and customized sizes are available against request

We could supply your prime best quality AISI 440C stainless steel for your different application use, no matter big quantity or small. You are welcome to contact us for any requests of 440c steel materials. Please subscribe our newsletters to have the promotion price list for 440c stainless steel frequently.

Property

Forging of 440C Stainless Steel

Preheat to 760oC – 820oC, then heat slowly and uniformly to 1050oC – 1150oC, hold until temperature is uniform throughout the 440c steel section and commence forging immediately. Do not overheat 440c stainless steel as this can cause a loss of toughness and ductility. Do not forge below 900oC. Finished forgings of SS 440c should be cooled slowly in a furnace, warm dry lime or ashes to room temperature and annealed immediately. Air cooling after forging may cause cracking of steel 440c.

Machinability of 440C Steel

ASTM Grade 440C stainless steel can be machined well, with all operations such as turning and drilling etc., in the annealed condition. Because of 440C SS high carbon content it machines somewhat like high-speed steel. Because chips are tough and stringy, chip curlers and breakers are important. As heat treated, the 440 steel series are difficult to machine because of their high hardness. For parts that require extensive machining, the free-machining versions, Type 440F or Type 440F Se, offer improved machining properties.

Welding of Stainless Steel 440C

Because of its high-hardness capability, and it can be easily air hardened, the 440c stainless steel is seldom welded. However, if welding is necessary, it should be preheated to 260°C (500°F) and post weld anneal treated at 732-760°C (1350-1400°F) for 6 h followed by slowly cooling in the furnace to prevent cracking. To obtain mechanical properties in the weld similar to those in the base metal, welding consumables of like composition should be considered. Otherwise, AWS E/ER309 might also be considered.

Heat Treatment of 440C Stainless Steel

* Hot Working

AISI grade 440C stainless steel is pre-heated at 760°C (1400°F). Temperature can be increased up to 1038-1204°C (1900-2200°F). It should not be heated below 927°C (1700°F). It is then slowly cooled at room temperature and fully annealed.

* Cold Working

ASTM Grade Steel 440C is slightly cold workable using common practices.

* Annealing of 440C Steel

For maximum softness, AISI 440C steel is annealed at 843-871°C (1550-1600°F), followed by slowly cooling in the furnace.

* Tempering of 440C Stainless Steel

Stainless 440C steel can be tempered by soaking at 148°C (300°F). Steel 440c hardness at approximately Rockwell C 60 will be obtained. To remove peak stresses and yet retain maximum hardness, temper at least one hour at 300/350ºF (149/177ºC).

* Hardening of 440C Steel

Stainless steel 440C grade can be hardened by heating at 760°C (1400°F). Temperature can be increased up to 1010°C (1850°F) followed by quenching in warm oil or cool in air. However, don’t overheat, because when overheated, full hardness cannot be obtained.

Corrosion Resistance

AISI stainless 440C steel has a corrosion resistance somewhat similar to 410 grade, but lower than 431 grade, also lower than most of the 400 series ferritic stainless steels and all of the 300 series austenitic stainless steels.

Applications

ASTM 440C steel has been widely used for parts requiring a combination of excellent wear resistance, plus reasonable corrosion resistance.

ASTM Stainless Steel 440C is used typically in the following applications:

* Cutlery

* Ball bearings and races

* Molds and dies

* High quality knife blades

* Valve components, pump parts,

* Measuring instruments, Surgical instruments

* Wear-resistant textile components.

Preheat to 760oC – 820oC, then heat slowly and uniformly to 1050oC – 1150oC, hold until temperature is uniform throughout the 440c steel section and commence forging immediately. Do not overheat 440c stainless steel as this can cause a loss of toughness and ductility. Do not forge below 900oC. Finished forgings of SS 440c should be cooled slowly in a furnace, warm dry lime or ashes to room temperature and annealed immediately. Air cooling after forging may cause cracking of steel 440c.

Machinability of 440C Steel

ASTM Grade 440C stainless steel can be machined well, with all operations such as turning and drilling etc., in the annealed condition. Because of 440C SS high carbon content it machines somewhat like high-speed steel. Because chips are tough and stringy, chip curlers and breakers are important. As heat treated, the 440 steel series are difficult to machine because of their high hardness. For parts that require extensive machining, the free-machining versions, Type 440F or Type 440F Se, offer improved machining properties.

Welding of Stainless Steel 440C

Because of its high-hardness capability, and it can be easily air hardened, the 440c stainless steel is seldom welded. However, if welding is necessary, it should be preheated to 260°C (500°F) and post weld anneal treated at 732-760°C (1350-1400°F) for 6 h followed by slowly cooling in the furnace to prevent cracking. To obtain mechanical properties in the weld similar to those in the base metal, welding consumables of like composition should be considered. Otherwise, AWS E/ER309 might also be considered.

Heat Treatment of 440C Stainless Steel

* Hot Working

AISI grade 440C stainless steel is pre-heated at 760°C (1400°F). Temperature can be increased up to 1038-1204°C (1900-2200°F). It should not be heated below 927°C (1700°F). It is then slowly cooled at room temperature and fully annealed.

* Cold Working

ASTM Grade Steel 440C is slightly cold workable using common practices.

* Annealing of 440C Steel

For maximum softness, AISI 440C steel is annealed at 843-871°C (1550-1600°F), followed by slowly cooling in the furnace.

* Tempering of 440C Stainless Steel

Stainless 440C steel can be tempered by soaking at 148°C (300°F). Steel 440c hardness at approximately Rockwell C 60 will be obtained. To remove peak stresses and yet retain maximum hardness, temper at least one hour at 300/350ºF (149/177ºC).

* Hardening of 440C Steel

Stainless steel 440C grade can be hardened by heating at 760°C (1400°F). Temperature can be increased up to 1010°C (1850°F) followed by quenching in warm oil or cool in air. However, don’t overheat, because when overheated, full hardness cannot be obtained.

Corrosion Resistance

AISI stainless 440C steel has a corrosion resistance somewhat similar to 410 grade, but lower than 431 grade, also lower than most of the 400 series ferritic stainless steels and all of the 300 series austenitic stainless steels.

Applications

ASTM 440C steel has been widely used for parts requiring a combination of excellent wear resistance, plus reasonable corrosion resistance.

ASTM Stainless Steel 440C is used typically in the following applications:

* Cutlery

* Ball bearings and races

* Molds and dies

* High quality knife blades

* Valve components, pump parts,

* Measuring instruments, Surgical instruments

* Wear-resistant textile components.