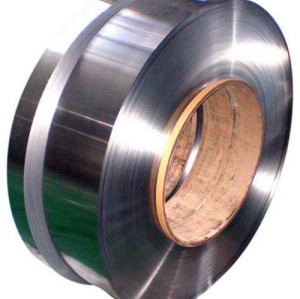

1.4002 X6CrAl13 Cold Rolled Ferritic Stainless Steel Narrow Strip

Review

Description

1.4002 X6CrAl13 Cold Rolled Ferritic Stainless Steel Narrow Strip

Introduce

1.4002 / DIN X6CrAl13 – AISI 405 – UNS S40500

1.4002 stainless steel is a corrosion resistant ferritic stainless steel formulated for primary forming into forged products with improved welding properties. The alloyed aluminum content reduces the tendency to harden in addition to the weld seam, thus minimizing susceptibility to cracking. Its properties are suitable for annealed condition. 1.4002 is the DIN norm of this material. X6CrAl13 is the EN chemical designation. 405 is the AISI definition of this material. S40500 is the UNS number. Additionally, the British Standard (BS) designation is 405S17. Its properties are medium corrosion resistance, good polishability, good weldability, good magnetisation, good chemical resistance, medium machinability.

It has a very high thermal conductivity among machined ferritic stainless steels. In addition, it has a fairly low embodied energy and a moderately low basic cost.

You can find the chemical properties of 1.4002 ferritic stainless steel in the following material properties.

405 is 12% chrome steel designed to be used as welded. Unlike other 12% chrome steels, it is not subject to much hardening by air cooling. It creates high temperatures.

Fields of application are generally used for annealing boxes, steam nozzles, quenching racks, compartments and other fabrications. It cannot be annealed after welding.

Chemical Composition

EN10088-2 Grade X6CrAl13 (1.4002)stainless steel plate

Number | Grade | Chemical composition % | |||||||

C | Si | Mn | P | S | Cr | Ni | Others | ||

1.4002 | X6CrAl13 | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 12.00-14.00 | 0.60 | AL:0.1-0.3 |

Equivalent

Stainless steel equivalent grade table | ||||

Number | GB/T 20878-2007 | ASME SA240/SA240M | JIS G 4305-2012 | EN10088-2-2014 |

S40500 | 06Cr13Al | 405 | SUS405 | 1.4002,X6CrAl13 |