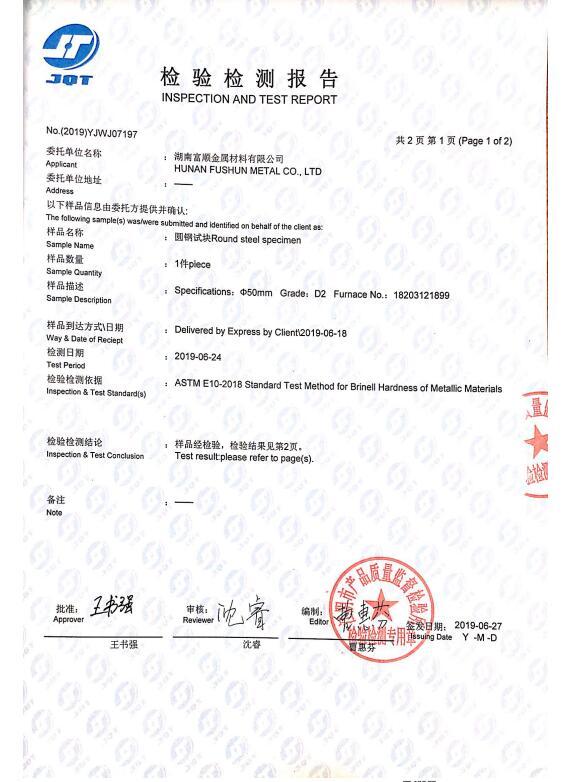

1.2379 D2 SKD11 Cold Work Tool Steel

- Model

- 1.2379 D2 SKD11 x153crmov12

Item specifics

- size range

- 5.5-500mm

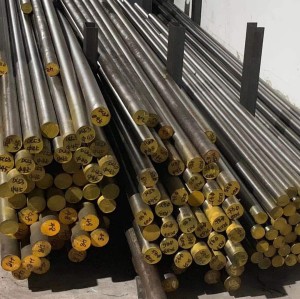

- shape

- round

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

Introduce:

This material is used in punching, cold solid forming, deep drawing, coining and cold extrusion processing methods. During cold solid forming, materials are transformed into their final shape by cold forming or extrusion. Depending on the method employed, the forming tools can be exposed to extremely high wear resulting from pressure and abrasion.The coining or embossing process, especially the minting of coins, creates unusually high demands on the steels used for punches and dies when it comes to purity, compression strength and wear resistance.

In the mints where the coins are produced, even the slightest divergences relating to surface, dimensional or gravimetric accuracy result in the tools being taken out of service. This strongly underlines the importance of the tool steel quality employed.

Standard:

Similar Grades:

ASTM | Material No. | DIN | EN |

D2 | 1.2379 | X155CrVMo12-1 | X160CrMoV121 |

Chemical Composition:

Grade | C | Mn | Si | P | S | Cr | Mo | V |

1.2379 | 1.45-1.6 | 0.20-0.60 | 0.10-0.6 | 0.03 max | 0.03 max | 11.0-13.0 | 0.7-1.0 | 0.7-1.0 |

Size & Process

Round Size Rnage:300-1000mm

Steel-making:EF/EAF+LF+VD EF/EAF+ESR

Process: Hot Rolleed or Hot Forged

Delivery condition: Annealed

Surface condition: Bright

Heat treatment:

Annealed(+A) max: 255HB

Annealing: slow cooling at 650ºC-850ºCfurnace

Quenching: Preheat 650ºC~750ºC increased to 1010ºC, air-cooled, or into the 996ºC to keep the salt bath, then cooled.

Tempering: The cold work D2 tool steel general tempering temperature is 170ºC-190ºC , Double tempering of Double tempering of D2 tool steel is recommended.