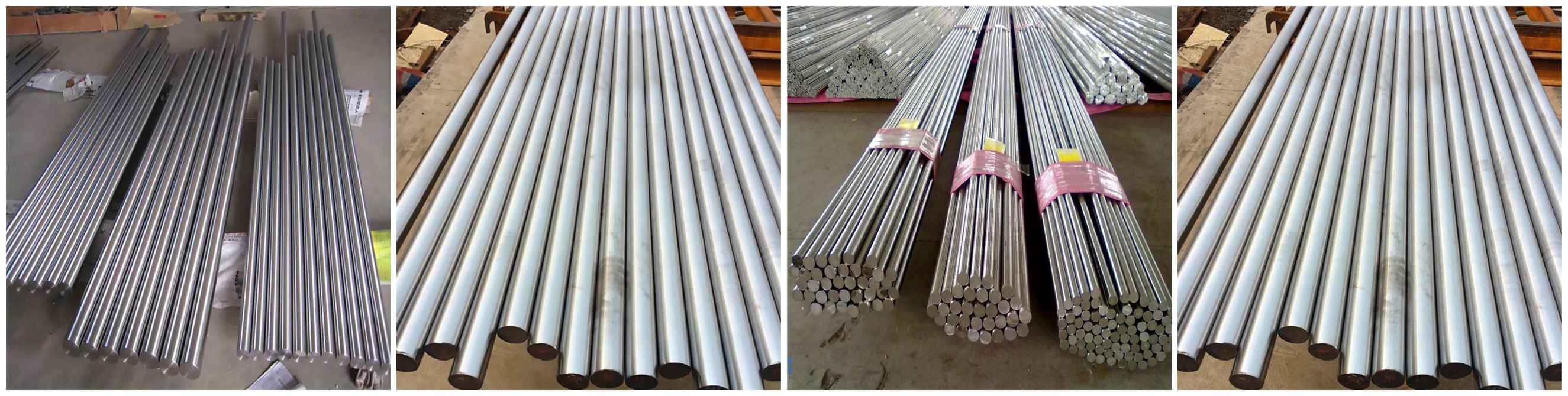

Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel Alloy Bar

- Model

- Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876

Item specifics

- Diameter Range

- 10-300mm

- Length Range

- 1000-9000mm

- Delivery Condition

- Annealed

- Surface Condition

- Bright

Review

Description

Introduce

Incoloy 800 (UNS N08800, W. Nr. 1.4876) is a widely used material for construction of equipment requiring corrosion resistance, heat resistance, strength, and stability for service up to 1500°F (816°C). Alloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength.

Applications

Incoloy 800 is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays, and fixtures. In chemical and petrochemical processing, the alloy is used for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in domestic appliances for sheathing of electric heating elements. In the production of paper pulp, digester-liquor heaters are often made of alloy 800. In petroleum processing, the alloy is used for heat exchangers that air cool the process stream.

Standard

Plate, Sheet, and Strip:

Pipe and Tubes:

Other Product Forms:

Chemical Composition

Grade | Al | C | Co | Cr | Cu | Fe | Mn | N | Ni | P | S | Si | Ti |

Alloy 800 | 0.3 | 0.015 | 0.01 | 22 | 0.75 | Bal | 0.25 | 0.03 | 34 | 0.2 | 0.02 | 0.5 | 0.5 |

Mechanical Properties

Alloy | Form | Condition | Ultimate Tensile Strength, ksi (MPa) | Yield Strength at 0.2% offset, ksi (MPa) | Elongation in 2" or 4D, percent |

800 | Sheet, Plate | Annealed | 85 (586) | 40 (276) | 43 |

800 | Sheet, Plate Strip, Bar | Annealed | 75 (520)* | 30 (205)* | 30* |

800H | Sheet, Plate | SHT | 80 (552) | 35 (241) | 47 |

800H | Sheet, Plate Strip, Bar | SHT | 65 (450)* | 25 (170)* | 30* |

Property

Machinability

Machining characteristics of this INCOLOY alloy 800 are similar to that of iron-based alloys. This alloy tends to work-harden during machining.

Welding

INCOLOY alloy 800 can be welded by common welding techniques, using a matching filler metal.

Forming

This alloy exhibits good ductility and hence can be formed using conventional methods.

Hot working

INCOLOY alloy 800 can be hot worked at temperature ranges of 871-1232°C (1600-2250°F).

Cold Working

Cold working may be done on the alloy using standard tooling.

Annealing

INCOLOY alloy 800 may be annealed after cold working. Annealing should be done at 982°C (1800°F) for 15 min and then the alloy should be air cooled.