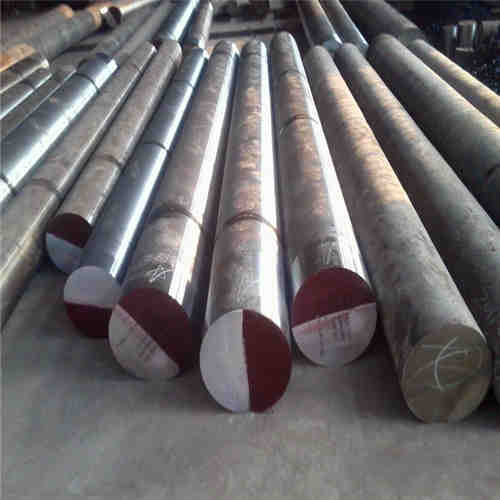

H13 1.2344 SKD61 Hot Work Tool Steel

- Model

- H13 1.2344 SKD61

Item specifics

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

H13 1.2344 SKD61 Hot Work Tool Steel

Introduction:

H13 steel is the most popular and most versatile, hot work mould steel, providing a good balance of toughness, heat check resistance, and high temperature strength, in addition to moderate wear resistance. H13 steel can resist softening to 550°C and has good resistance to heat checking. Will Nitride with a case hardness over 1000 V.P.N. Generally supplied annealed to HB 230 max.

Process:

H13 material is softer during hot forging, in order to avoid excessive bending, the production length of ordinary forging machines is not more than 9 meters, in the case of Radial forging equipment, the H13 steel forging rounds bar can reach a maximum of 15 meters.

In production, H13 ingots need slowly cooled. After ingot release mould, it need take annealed before being forged.

As delivery for clients, H13 recommends annealing + surface bright( remove the black oxide skin), because the high nickel element is prone to surface cracking.

Ultrafine Treatment

The steel's microstructure is effectively refined by the multiple cycle heating and quenching method. The specific process is to heat the steel from room temperature to a temperature slightly above Ac3, hold it for a short time at a lower austenitizing temperature, then quickly quench and cool it to room temperature, and repeat the process. Each cycle heating will obtain more fine austenitic grains.

Applications:

H13 steel is an air hardening, 5% chromium die steel, which is an excellent choice for a wide range of hot work and cold work applications. Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners, mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. H13 steel is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies.

General Properties:

H13 steel is characterized by

Good resistance to abrasion at both low and high temperatures.

High level of toughness and ductility Uniform and high level of machinability and polishability.

Good high-temperature strength and resistance to thermal fatigue.

Excellent through-hardening properties.

Very limited distortion during hardening.

Good machinability.

Quality Standard:

ASTM A681 Standard Specification for Tool Steel

All Grades Comparison:

AS 1239 | ASTM A 681 | BS 4659 | BS EN ISO 4957 | JIS G 4404 | Werkstoff |

|---|---|---|---|---|---|

H13A | H13/UNS T20813 | BH13 | X40CrMoV 5-1 | SKD 61 | 1.2344/X40CrMoV5-1 |

Chemical Composition(%):

Steel Grade | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|

H13 | 0.32-0.45 | 0.90-1.25 | 0.20-0.60 | 0.030 max | 0.030 max | 4.75-5.50 | 1.10-1.75 | 0.80-1.25 |

DIN1.2344 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.030 max | 4.80-5.50 | 1.20-1.50 | 0.80-1.15 |

SKD61 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.020 max | 4.80-5.50 | 1.00-1.50 | 0.80-1.15 |

Typical Hardness/Applications – Air cooled at 1020°C–1050°C & tempered:

Temper | HRC | Typical Applications |

|---|---|---|

500°C | 53–55 | Swaging dies |

550°C | 52-54 | Ejector pins & nozzles for tin, lead or zinc die casting |

575°C | 50–52 | Blanking & bending dies. Aluminium die casting dies |

600°C | 47–50 | Gripper and header dies |

610°C | 46–49 | Forging dies and inserts, extrusion dies, mandrels |

620°C | 44–48 | Hot shears, forming dies and punches |

Welding:

In general, we do not advise the welding of tool steel but users sometimes prefer to weld in order to avoid the cost of retooling. It should be remembered that this grade is an air hardening steel and that in welding the area of the weld attains a temperature of about 1000°C. Cracking is likely to occur during cooling unless proper precautions are taken. Popular methods of welding are atomic hydrogen and argon arc. We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding tool steels.

Welding Procedure

It is desirable to anneal the tool prior to welding but with care welding may be done on hardened and tempered tools.

It is important to preheat the die to 300-500°C and to maintain this temperature during welding.

After the weld has been completed, maintain at 300-500°C for one hour, then cool the die slowly in a furnace or in insulating material.

If the tool has been annealed prior to welding, stress relieve at 700°C before re-hardening.

If the tool has not been annealed prior to welding, re-temper at 550-600°C for a minimum of 2 hours.

Final Grinding:

Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure the grinding wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a copious supply of coolant. If dry grinding is resorted to then use a very soft wheel.

Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.