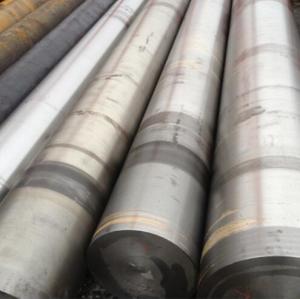

4Cr5MoSiV Hot Work Tool Steel

- Model

- 4Cr5MoSiV

Item specifics

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

4Cr5MoSiV Hot Work Tool Steel

4Cr5MoSiV Introduction:

Alloy tool steel for hot working for moulds for die casting of aluminium alloys, magnet, zinc, pressing pipes, copper alloy bars and light metals under pressure.It is characterized by very high hardenability, resistance to tempering, possibility of working at high temperatures and low susceptibility to forming a surface crack net.Disadvantages of the grade are low sensitivity to rapid temperature fluctuations during operation, low impact and shock resistance. Before use the tools must be warmed to a minimum temperature of 200 C, but must not exceed the tempering temperature.It is used for the production of hot working knives, die inserts for presses and forging machines, screws, dies, moulds for plastics, stamps, mandrels, punches, copper rolling mills.The steel is also available after ESR electroslag melting, which guarantees high purity - recommended for moulds for casting non-ferrous metal alloys under pressure, and ESF which guarantees fine-grainability.

The tool steel 4Cr5MoSiV is a hot-work tool steel with high toughness and good heat resistance. 4Cr5MoSiV is hot cracking resistant and has good thermal conductivity. For particularly difficult applications, there is this material with a special high purity ( ESU-Quality), Frequently, this material is used to manufacture extrusion. Usually 4Cr5MoSiV is supplied in the soft-annealed condition.

4Cr5MoSiV Applications:

4Cr5MoSiV Hot Work Steels is often used for highly stressed structural parts such as aircraft landing gear. It resists softening at temperatures up to 1000 F while retaining good ductility and toughness even at strength levels on the order of 275 ksi.

4Cr5MoSiV Chemical Composition(%):

C | Si | Mn | P | S | Cr | V | Mo |

0.33-0.43 | 0.80-1.25 | 0.20-0.60 | 0.030 max | 0.030 max | 4.75-5.50 | 0.30-0.60 | 1.10-1.60 |

4Cr5MoSiV HEAT TREATMENT:

FORGING: 4Cr5MoSiV hot work steels are forged at 1121°C (2050°F). For this type of steels, forging below 899°C (1650°F) is not preferable.

ANNEALING: 4Cr5MoSiV hot work steels are annealed at 871°C (1600°F) and slowly cooled at 4°C (40°F) in the furnace.

HARDENING: Preheat to 1500 F and then heat to 1850 F and hold for 15 to 40 minutes. Air cool (air quench).

TEMPERING: Tempering is carried out on 4Cr5MoSiV tool steels at temperature ranging from 538 to 649°C (1000 to 1200°F) to obtain Rockwell C hardness of 54 to 38. Double tempering can also be performed in these steels every one hour at the preferred tempering temperature.

4Cr5MoSiV Mechanical Properties:

Properties | Metric | Imperial |

Hardness, Rockwell C (air cooled from 982°C, 45 mins) | 52.5 | 52.5 |

Hardness, Rockwell C (air cooled from 1010°C, 45 mins) | 56 | 56 |

Hardness, Rockwell C (air cooled from 1038°C, 45 mins) | 57 | 57 |

Modulus of elasticity | 207 GPa | 30000 ksi |

Modulus of elasticity (@538°C/1000°F) | 159 GPa | 23000 ksi |

Modulus of elasticity (@204°C/400°F) | 190 GPa | 27500 ksi |

Charpy impact (V-notch; air cooled from 1010°C;535°C temper temperature) | 13.6 J | 10.0 ft-lb |

Charpy impact (V-notch; air cooled from 1010°C;650°C temper temperature) | 27.1 J | 20.0 ft-lb |

Charpy impact (V-notch; air cooled from 1010°C;370°C temper temperature) | 33.9 J | 25.0 ft-lb |

Machinability (1% carbon steel) | 75.0 – 80.0% | 75.0 – 80.0% |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

4Cr5MoSiV Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.