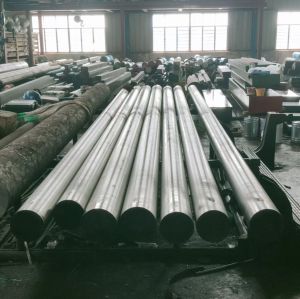

1.2162 21MnCr5 20ХГ Cold Work Tool Steel Round Bar

- Model

- 1.2162 21MnCr5 20ХГ

Item specifics

- Delivery Condition

- +N or +A or +QT

- Surface Condition

- black or turned or polished

Review

Description

1.2162 21MnCr5 20ХГ Cold Work Tool Steel Round Bar

Grade : 21MnCr5

Number: 1.2162

Classification: Alloy cold-work tool steel

Standard: EN ISO 4957: 2000 Tool steels

Our supply size :

Diameter : 80 to 600 mm ;

Length : 1000 to 9000 mm ;

Our capacity :

Delivery condition : Normalized, or Annealed, or Quenched and Tempered ;

Surface condition : Grounded, or Turned, or Polished

Our advantage :

1. High Quality, Reasonable Price

2. Over 40 Years Experience

3. ISO NQA Certificated Factory

4. Worldwide shipping

5. Emergency Orders and Fast Delivery

Characteristics

Manganese-chrome steel for case-hardening with the middle hardenability, with the hardness of case-hardened layer and with the high hardness in the core. Further the steel is characterized by a good ductility at the heat, good workability in the annealed state and it is easy to polish.

APPLICATION:

machine parts and moulding plates with a high surface hardness;

synthetic resin press moulds for the processing of thermoplastics and thermosetting plastics.

Suitability

For small and middle-size cemented molds for mechanical working of plastic materials and rubber with the demand on higher hardness in the core.

Chemical composition%of the ladle analysis of grade 1.2162

C | Si | Mn | P | S | Cr |

0.18 - 0.24 | 0.15 - 0.35 | 1.1 - 1.4 | max 0.03 | max 0.03 | 1 - 1.3 |

HEAT TREATMENT:

Soft annealing:

670 to 710 °C for about 2 to 5 hours

slow controlled cooling, further cooling in air, max. 205 HB

Carburising:

900 to 950 °C. The choice of the carburising means and carburising temperature depends on the desired surface carbon content, the carburising graph and the required case depth.

Application:

870 to 930 °C in powder/salt bath, cooling in oil/warm bath at 160 to 250 °C

Intermediate stress-relieving heat treatment:

630 to 650 °C, about 2 to 4 hours with slow furnace cooling

Preheating:

350 °C depending on dimensions

Hardening:

curing temperature 810 to 840 °C in oil of ~ 60 °C warmth

Cooling:

down to about 100 °C in oil, then in air to about 50 °C

Tempering:

1 hour per 20 mm part thickness, at least 2 hours

Mill′s test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Surface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)