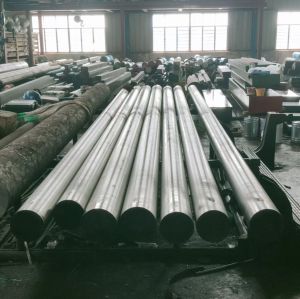

A2 1.2363 SKD12 Cold Work Tool Steel

- Model

- A2

Item specifics

- Diameter

- 50-550mm

- Similar steel grades

- A2,1.2363, X100CrMoV5,X100CrMoV 5

- Delivery condition

- Annealed

- Surface

- peeled

Review

Description

Introduction of A2 steel:

AISI A2 Tool Steel Bar, with maximum dimensional stability during heat treatment, offering high abrasion resistance and good toughness. Generally supplied annealed to HB 231 max. A2 tool steel is an air hardening, cold work tool steel. A 5% Chromium steel which provides high hardness after heat treatment with good dimensional stability. It is heat treatable and will offer a hardness in the range 57-62 HRC.

Application of A2 steel:

AISI A2 tool steel takes a place in tool steel range between AISI O1 tool steel and AISI D2 tool steel, offering an excellent combination of good wear resistance and toughness. It may be regarded, therefore, as a “universal” cold work tool steel. For cutting operations the good toughness of AISI A2 tool steel gives excellent resistance to chipping of the cutting edge. In many cases tools made from this steel have given better tooling economy than high-carbon, high-chromium steels of the D3/W.-Nr. 1.2080 type.

AISI A2 tool steel has much better machining and grinding properties.It can be used to make Bending Dies, Blanking Dies, Block Gauges, Cams, Coining Dies, Cold Forming Dies, Cold Shears, Cold Trimming Dies, Forming Dies, Knurls, Machine Parts, Mandrels, Plastic Mold Dies, Punch Plates, Punchers, Reamers, Ring Gauges, Roll Threading Dies, Rolls, Shear Blades, Slitters, Stamping Dies, Threading Taps, Trimming Dies, etc.

Chemical Composition of A2 steel(%):

C | Si | Mn | P | S | Cr | Mo | V |

0.95-1.05 | 0.10-0.50 | 0.40-1.00 | 0.030 max | 0.030 max | 4.75-5.50 | 0.90-1.40 | 0.15-0.50 |

Similar steel grades of A2 steel:

ASTM A681 | Werkstoff | BS 4659 | BS EN ISO 4957 | AFNOR | AS | JIS G4404 |

A2 | 1.2363/X100CrMoV5 | BA2 | X100CrMoV 5 | Z 100 CDV 5 | A2A | SKD 12 |