1.2767 45NiCrMo16 Tool Steel Flat

- Model

- 1.2767 45NiCrMo16

Item specifics

- Delivery Condition

- +N or +A or +QT

- Surface Condition

- black or turned or polished

Review

Description

1.2767 45NiCrMo16 Cold Work Tool Steel

1.2767 45NiCrMo16 is a higher carbon version of the standard 4¼% nickel air/oil hardening steel. 1.2767 achieves a good hardness and is suitable for applications demanding extra wear resistance.

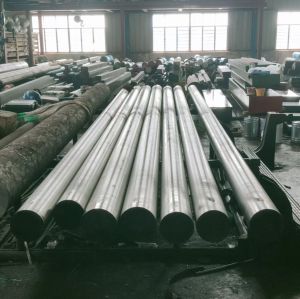

Our supply size :

Width : 100 to 800 mm ;

Thickness : 20 to 300 mm

Length : 1000 to 9000 mm ;

Our capacity :

Delivery condition : Normalized, or Annealed, or Quenched and Tempered ;

Surface condition : Grounded, or Turned, or Polished

Our advantage :

1. High Quality, Reasonable Price

2. Over 40 Years Experience

3. ISO NQA Certificated Factory

4. Worldwide shipping

5. Emergency Orders and Fast Delivery

Equivalent grades

Standards | DIN | AISI | JIS | ГОСТ |

45NiCrMo16 | 1.2767 | 6F7 | SKT6 | 40Х2Н4МА |

Chemical composition (typical analysis in %)

C | Si | Mn | P | S | Cr | Mo | Ni |

0.40-0.50 | 0.10-0.40 | 0.15-0.45 | ≤0.030 | ≤0.030 | 1.20-1.50 | 0.15-0.35 | 3.80-4.30 |

Characteristics

Material properties: Due to the high nickel and corresponding carbon content, this material is a very evenly hardening, dimensionally stable steel with high toughness and resistance to impact and compressive stress.

1.2767 is Nickel cold work tool steel. Good hardenability and thougness. Ability for polishing, photoetching and erosion treatment. Application include forging tools, dies of all sort, shapes and sizes, hot forging and pressing tools for steel and metal. Moulds, bushings, piercers, etc.

Application

Mould plates and inserts for the processing of thermo- plastics and thermosets, especially for high gloss polishes, e.g. for transparent melts and components with high surface requirements, mould components with high compressive and flexural stresses, embossing tools and other uses for which the above requirements are needed.

Heat treatment

Hardening:

At 840°C – 870°C. Details can be found in the time-temperature conversion and tempering charts. The most suitable heat treatment for the relevant workpiece should be fixed by the hardening shop. The hardness should be specified by the hardening shop and checked on delivery.

Soft annealing:

620°C – 650°C, approx. 4 h

Stress-relief annealing:

To eliminate residual stresses after coarse machining at approx. 600°C – 650°C, approx. 4 h with slow heating and furnace cooling.

Normal working hardness:50 - 56 HRC

Mill′s test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Surface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)