JIS G3447 Stainless Steel Sanitary Pipes

Item specifics

- Length range

- 50-12000mm

Review

Description

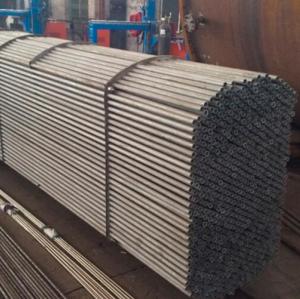

JIS G3447 Stainless Steel Sanitary Pipes

JIS G3447 stainless steel sanitary pipes used for the dairy, food industry

JIS G3447 Stainless Steel Sanitary Pipes Method of manufacture

The method of manufacturing pipes shall be as follows.

(1) Pipes shall be manufactured by a seamless process, of be manufactured by an automatic arc welding, laser welding of electric resistance welding.

(2) Pipes shall be solution-treated (rapid cooling after heating at 1010 o C of higher).

JIS G3447 Stainless Steel Sanitary Pipes Dimensions and dimensional tolerances

Outside diameter mm : 10-300

Thickness mm : 1-10

Length m: 4 /6 /random

tolerances : OD +/- 0.15mm ; WT +/-10 %

JIS G3447 Stainless Steel Sanitary Pipes Chemical Component

Symbol of grade | c | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

SUS 304TBS | 0.08 max. | 1.00 max | 2.00 max | 0.040 max | 0.030 max | 8.00 to 11.00 | 18.00 to 20.00 | / |

SUS 304LTBS | 0.030 max | 1.00 max | 2.00 max | 0.040 max | 0.030 max | 9.00 to 13.00 | / | / |

SUS 316TBS | 0.08 max. | 1.00 max | 2.00 max | 0.040 max | 0.030 max | 10.00 to 14.00 | 16.00 to 18.00 | 2.00 to 3.00 |

SUS 316LTBS | 0.030 max | 1.00 max | 2.00 max | 0.040 max | 0.030 max | 12.00 to 16.00 | 16.00 to 18.00 | 2.00 to 3.00 |

Hydraulic of pneumatic test characteristic, of nondestructive examination characteristic

Pipes shall be tested in accordance with 10.4, and the hydraulic or pneumatic test characteristic, of the nondestructive examination characteristic, of the pipe shall be in accordance with either of the following. Preference shall be left to the designation by the purchaser of the discretion of the manufacturer.

1 Hydraulic of pneumatic test characteristic

When subjected to the test of 10.4, pipes shall withstand the applied hydraulic pressure of 2.5 MPa of the applied pneumatic pressure of 0.6 MPa, being free form leakage.

2 Nondestructive examination characteristic Seamless steel pipes shall be examined by ultrasonic flaw detection of eddy current flaw detection, and welded steel pipes shall be examined by eddy current flaw detection. Then, there shall be no signal at least equal to that from the artificial defects of the reference test piece of working sensitivity division UD of JIS G 0582 or of working sensitivity division EY of JIS G 0583.

JIS G3447 Stainless Steel Sanitary Pipes Surface finish

Pipes shall be finished, as a rule, by abrasive grain size #400 polishing on both inner and outer faces. However, the purchaser can designate the surface to be finished and the

finished conditions.

JIS G3447 Stainless Steel Sanitary Pipes Appearance

The appearance shall be as follows.

(1) Pipes shall be practically straight, and their both ends shall be at right angles to the pipes axes.

(2) Both the internal and external surfaces of pipes shall be well finished and free from defects detrimental to use.

JIS G3447 Stainless Steel Sanitary Pipes Surface roughness

The surface roughness, in accordance with the specifications of ISO 468, shall be as follows.

Finely finished surface

1) ISO 1127: 1992 stainless steel tube -dimensions, tolerances and conventional masses per unit length.

2) ISO 2604-2: steel products for pressure purposes quality requirements -Part 2 : Wrought seamless tubes

3) ISO 2604-5: 1978 Steel product for pressure purposes Quality requirements- Longitudinally welded austenitic stainless steel tubes

4) ISO 4200: 1991 Plain end steel tubes, welded and seamless- General table of dimensions and masses per unit length

JIS G3447 Stainless Steel Sanitary Pipes Making

Pipes having passed the inspection shall be marked with the following items on each package or bundle.

The order of markings are not specified. A part thereof may be omitted as approved by the purchaser.

(1) Symbol of glade

(3) Dimensions

(4) Manufacturer's name or abbreviation

(5) Symbol z indicating the designation of special quality requirements

We also can supply other kinds of:

Seamless Stainless Steel Pipe&Tube

Welded Stainless Steel Pipe&Tube

U Type Stainless Steel Pipe&Tube

Coil Type Stainless Steel Pipe&Tube(Max 300meter),seamless or welded

Annealed Pickled AP Stainless Steel Pipe&Tube(Ra≤2.5μm)

Bright Annealed BA Stainless Steel Pipe&Tube(Ra≤0.8μm)

Mechanical Polished MP Stainless Steel Pipe&Tube(Ra≤0.8μm)

Electro Polished EP Stainless Steel Pipe&Tube(Ra≤0.25μm)

Sanitary Stainless Steel Pipe&Tube

Capillary Stainless Steel Pipe&Tube

Instrument Stainless Steel Pipe&Tube

Contact Fushun JIS G3447 Stainless Steel Sanitary Pipes Today

Contact us for more information regarding precision steel tubing specifications and product options, or request a quote for further pricing details today.