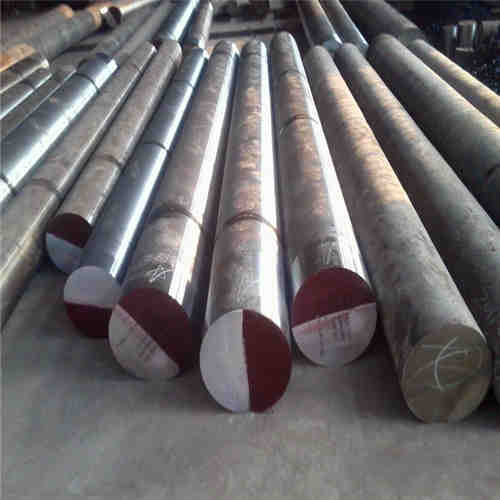

1.2562 142W12 Cold Work Tool Steel

- Model

- 1.2562 142W12

Item specifics

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

1.2562 142W12 Cold Work Tool Steel

Description

Low alloyed W cold working tool steel.The high quality Germany DIN 1.2562 material is one of the more steel grades we supply, Alloyed WV steel.

Applications

Cutting tools, stamping, woodworking, drawing, deep drawing and pressing tools, cold working rolls, measuring tools.

Chemical Composition (in weight %)

Grade | C | Si | Mn | Cr | V | W |

1.2562 | 1.43 | 0.23 | 0.30 | 0.35 | 0.25 | 3.05 |

Mechanical Properties of 1.2562

Rp0.2 (MPa) | Rm (MPa) | Impact KV (J) | Elongation A (%) | A Z (%) | Delivery | Hardness HB |

715 (≥) | 459 (≥) | 31 | 34 | 23 | Solution & Aging, Ann, Ausaging, Q+T | 314 |

Soft Annealing

Heat to 720-750℃, cool slowly in furnace. This will produce a maximum Brinell hardness of 270.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to approx. 650℃, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 800-830℃ followed by water quenching. Hardness after quenching is 66 HRC.

Tempering

Tempering temperature: 100-250℃.

Forging

Hot forming temperature: 1050-850℃.