SK5 High Carbon Tool Steel

- Model

- SK5

Item specifics

- type

- high carbon

Review

Description

Sk5 is a Japanese high carbon steel. It’s used in a wide range of tools (Razor blades, utility knives, scalpel blades, long edged tools, cutting tools) due to its workability, hardenability, price, and other features.

After quenching and tempering, sk5 steel has high hardness and wear resistance. SK5 high carbon steel is used to make various tools which request high hardness and wear resistance, such as the shape of the mold and the simple punch, metal cutting tools, drilling tools, woodworking cutter, countersink drills, axes, chisels, hand saws longitudinal and fitter assembly tools, rivet die and other minor tools. We can supply SK5 steel in hardened & tempered process and annealing process.

JIS-SK5

C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Cu(%) |

0.8-0.9 | 0.15-0.35 | 0.15-0.5 | ≦0.03 | ≦0.03 | ≦0.3 | ≦0.25 | ≦0.25 |

Steel SK5 (JIS ) and its European equivalent C90U (1.1535) ( EN )

EU | USA | Germany | Japan | France | Italy | China | Poland | Czechia | Austria | Russia | |||||||||||

C90U (1.1535) |

|

|

|

|

|

|

|

|

|

|

Steel SK5 (JIS ) and its European equivalent C80U (1.1525) ( EN )

EU | Germany | Japan | France | England | Italy | China | Poland | Czechia | Austria | Russia | ||||||||||||

C80U (1.1525) |

|

|

|

|

|

|

|

|

|

|

| TOKKIN Designation | Chemical composition(%) | ||||||||

C | Si | Mn | P | S | Cr | Ni | Mo | その他 | ||

Special steel | TE2 | 1.20 ~1.30 | 0.15 ~0.35 | ≦0.35 | ≦0.030 | ≦0.020 | 0.30 ~0.50 | ≦0.25 | -- | Cu≦0.25 |

SK2 | 1.15 ~1.25 | 0.10 ~0.35 | 0.10 ~0.50 | ≦0.030 | ≦0.030 | ≦0.30 | ≦0.25 | -- | Cu≦0.25 | |

SK4 | 0.90 ~1.00 | 0.10 ~0.35 | 0.10 ~0.50 | ≦0.030 | ≦0.030 | ≦0.30 | ≦0.25 | -- | Cu≦0.25 | |

SK5 | 0.80 ~0.90 | 0.10 ~0.35 | 0.10 ~0.50 | ≦0.030 | ≦0.030 | ≦0.30 | ≦0.25 | -- | Cu≦0.25 | |

Stainless steel | RB-S | 0.58 ~0.70 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.015 | 12.50 ~14.50 | -- | -- | -- |

RB-Z | 0.33 ~0.45 | ≦1.00 | ≦1.50 | ≦0.040 | ≦0.015 | 15.50 ~17.50 | ≦1.00 | 0.80 ~1.30 | -- | |

SUS420J2 | 0.26 ~0.40 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12.00 ~14.00 | -- | -- | -- | |

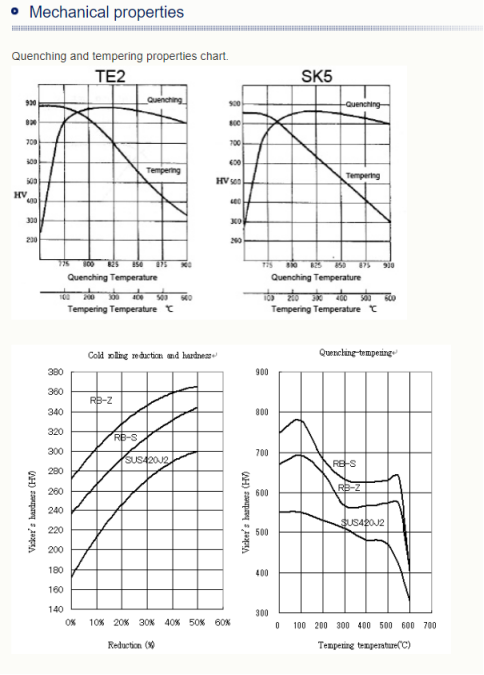

Physical properties

TOKKIN Designation | Density | Specific heat | Coefficient of thermal expansion | Thermal conductivity | Electric resistance | Young's modulus |

g/cm3 | J(kg・K) | (0~100゜C)10-6/K | W/(m・K) | μΩ・cm | N/mm2 | |

SK5(SK85) | 7.84 | 490 | 11.0 | 50.2 | 18 | 208,000 |

RB-S | 7.7 | 430 | -- | 25 | 60 | 220,000 |

SUS420J2 | 7.75 | 460 | 10.3 | 24.7 | 55 | 200,000 |

sk5 steel properties

According to the chemical composition and the HRC of the steel, the AEB L Steel has the following features:

sk5 Edge Retention: SK5 offers impressive edge, being carbon steel with close to 1%, makes it very hard steel with great edge retention.

sk5 Corrosion Resistance: sk5 offers decent corrosion resistance, not a bad one, but it must be taken care of to avoid future rust and corrosion.

sk5 Wear Resistance: Great wear resistance, thanks to the fine grain and Carbon carbides.

sk5 Sharpness: The rule says the harder the steel, the harder to sharpen it, SK5 can get very hard (62-63 HRC), which makes sharpening a bit hard.

sk5 Toughness: Sk5 is very tough steel with great impact resistance, the steel offers a great balance between hardness and toughness at the cost of corrosion resistance (you can’t have those three in one steel).

HOW SK-5 STEEL COMPARES

It is named after a Japanese scale but is similar in properties to the American 1080 steel, which is made up of approximately 0.80% carbon and up to 0.90% manganese. On the HRC scale, it ranks at approximately 65, which makes it a very hard steel. Its alloy increases its strength and abrasion resistance. It is a good, tough blade with a great edge-holding ability.

sk5 steel equivalent

Sk5 is very close to the carbon Steel W2 and 1084. They have a very close chemical composition, they all offer what “Carbon Steel” are good at EDGE RETENTION and TOUGHNESS, and they have decent corrosion resistance, and they fall in the same price range (low/mid-range price).

Yield | Tensile | Impact | Elongation | Reduction in cross section on fracture | As-Heat-Treated Condition | Brinell hardness (HBW) |

497 (≥) | 426 (≥) | 32 | 33 | 34 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 121 |

Product size range

Grade | Thickness (mm) | Width (mm) |

SK2 (SK120) | 0.010–2.000 | 3–300 |

SK4 (SK95) | 0.010–2.000 | 3–300 |

SK5 (SK85) | 0.010–3.500 | 3–300 |

SK6 (SK75) | 0.010–2.000 | 3–300 |

SK7 (SK65) | 0.010–1.600 | 3–300 |

Standard

| TOKKIN Designation | International Standard | USA | UK | Germany | France | Russia | China | Europe | Japan | |

ISO | UNS | AISI ASTM | BS | DIN | NF | ΓOCT | GB | EN | JIS | ||

Special steel | TE2 | -- | -- | -- | -- | -- | -- | -- | -- | -- | SK81M |

SK2 | TC120 | -- | W1-11 1/2H | -- | -- | C120E3U | Y12 | T12 | -- | SK120 | |

SK4 | TC90 | -- | W1-9 | -- | -- | C90E2U | Y10 | T10 | -- | SK95 | |

SK5 | TC90 TC80 | -- | W1-8 | -- | C80W1 | C90E2U C80E2U | Y8Γ Y9 | T8Mn T9 | -- | SK85 | |

Stainless steel | RB-S | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

RB-Z * | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | |

SUS420J2 | 5 | S42000 | S42000 | 420S45 | X30Cr13 | Z33C13 | 30X13 | 3Cr13 | X30Cr13 | SUS420J2 | |