1.2709 Hot Work Tool Steel

Item specifics

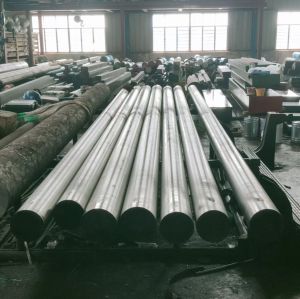

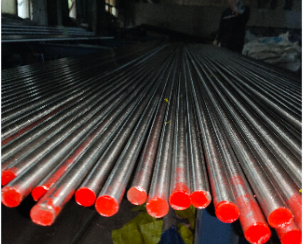

- Process

- hot rolled or hot forged

- Delivery Condtion

- annealed

- Surface Condition

- smooth, bright

Review

Description

1.2709 Hot Work Tool Steel

Tool steels such as 1.2709 are primarily used for manufacturing tools and molds. They are characterized by a high hardness combined with a high ductility. Their specific mechanical properties allow usage in high-stressed components due to its high wear resistance.The maximum operating temperatures can further reduce wear.An SLM-specific bene t is the layerwise manufacturing,which allows to implement cooling channels into the component.

Typical Applications

l Inserts for injection molding

l Inserts for die casting

l Tooling

l Material Numbers

Standard

UNS K93120

AMS 6521, 6514

ASTM Marage 300

Chemical composition%of the ladle analysis of grade1.2709

C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Co(%) | Ti(%) |

Max 0.03 | Max 0.10 | Max 0.15 | Max 0.010 | Max 0.010 | Max 0.025 | 17.0-19.0 | 4.50-5.20 | 8.50-10.0 | 0.80-1.20 |

Physical Properties

Properties | Value |

Density [g/cm3] | 8.0 |

Tensile strength UTS [MPa] | >1000 |

Yield strength [MPa] | >900 |

Young’s modulus [GPa] | >130 |

Elongation [%] | <13 |

Heat Treatment

EOS ToolSteel 1.2709 can be heat treated to match various needs of different applications.The two step heat treatment can be performed under vacuum or inert gas atmosphere.First step is solution annealing to minimize amount of austenite in the martensitic matrix. The needed hardness and strength is achieved through aging treatment where hardening takes place through

forming of intermetallic phases and precipitates.

Solution Annealing:

2 h at 940"C(+10"C)measured from the part followed by rapid air cooling to room temperature(below 32"C).Cooling rate 10-60"C/min. Reaching room temperature before starting aging treatment is required to achieve desired microstructure.

Aging:

For peak hardness and strength 3-6 h at 510'C(+10C)measured from the part followed by air cooling. Mechanical properties presented in this document achieved through this aging procedure.For bulky parts ensure uniformity of properties by increasing hold time up to 6 h.Also,

to maximize fatigue strength,a hold time of 6 h is recommended.