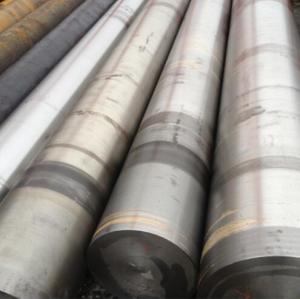

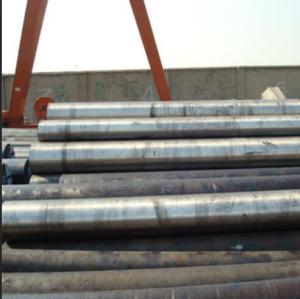

21CrMoV5-11 1.8070 21CrMoV5-7 1.7709 Hot Forged Alloy Steel Round Bar

- Model

- 21CrMoV5-11 1.8070 21CrMoV5-7 1.7709

Item specifics

- Standard

- EN 10269

- Applications

- steam turbines, rotor blades, shaft forgings, etc

- Heat treatment

- Normalized,Quenching and Tmenpering

- Surface condition

- Black or bright surface

Review

Description

Description of 1.8070 21CrMoV5-11

21CrMoV5-7 / 21CrMoV5-11 replacement alloys belong to the group of high temperature boiler steels for energy industries. They are used in the production of components/subassemblies for the power industry, working at the temperatures up to 550 ℃ for small parts and for large forgings.

Applications of 1.8070 21CrMoV5-11

The main applications of these grades of steel are rotors of steam turbines, rotor blades, shaft forgings, reservoirs and covers for up to 550 ℃ temperatures, nuts, tubes for high temperatures up to 540 ℃.

Chemical Composition(%) of 1.8070 21CrMoV5-11

Thermal treatment of 1.8070 21CrMoV5-11

Softening at 650 °C with slow cooling

Slow relief annealing at 530 °C at furnace to at least 200

Normalizing at 950 - 980℃ with cooling in calm air

Hardening at 930 - 950℃ in water, 940 - 960℃ in oil

Tempering at a temperature of 650 ° c in the air for many hours depending on the size of the material

Mechanical properties of 1.8070 21CrMoV5-11 +QT

Tensile strength, Rm = 700 - 850 MPa

Yield point, Re > 550 MPa

Elongation, A > 16%

Contraction, Z > 60%

Notch toughness, KV20℃ > 63 J

Hardness after annealed HBW: 205 ~ 250

Yield point at individual temperatures of 1.8070 21CrMoV5-11

Re przy 200℃ = 500 MPa

Re przy 300℃ = 460 MPa

Re przy 400℃ = 412 MPa

Re przy 500℃ = 334 MPa

Re przy 550℃ = 275 MPa

Permissible temperature of application of steel in hydrogen containing environments depends on its partial pressure 21CrMoV5-11

Creep limit and creep resistance of 21HMF / 21CrMoV5-11 / 1.8070 according to tests on rotors at 550 ℃