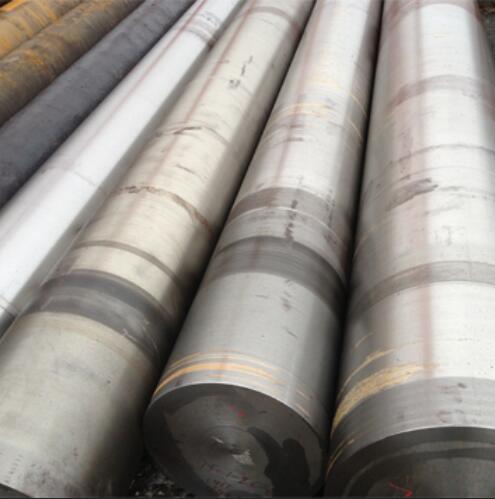

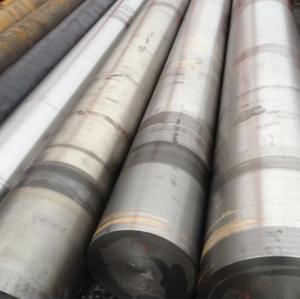

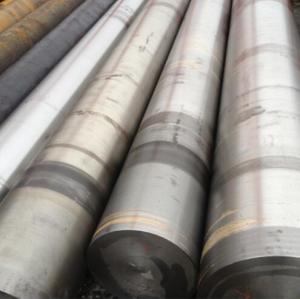

9840 Hot Forged Alloy Steel Round Bar

- Model

- AISI/SAE 9840 forged bar

Item specifics

- Diameter

- 200-800mm

- Applications

- forged propeller shafts, connecting rods, gear sh

- Heat treatment

- Normalized,Quenching and Tmenpering

- Surface condition

- Black or bright surface

Review

Description

Introduce of 9840 steel:

This is a nickel-chrome-molybdenum steel with excellent hardenability, strength and toughness.

Application of 9840 steel:

This alloy is suited to production of highly stressed components of large cross section for aircraft, automotive and general engineering applications, such as forged propeller shafts, connecting rods, gear shafts, crankshafts and landing gear components.

Forging of 9840 steel:

This alloy would be forged between 2150 and 1700ºF (1175 and 925ºC.)

Heat treatment of 9840 steel:

Annealing: Austenitize at 1525ºF (830ºC) and slow cool from 1280 to 1200ºF (iso anneal) to give coarse pearlite structure for optimum machinability.

Normalizing: At 1600ºF (870ºC) followed by air cool.

Hardening: from 1525-1575ºF (830-860ºC) and oil quench for thin, intricate shapes, water quench for large, simple shapes.

Tempering: from 1000-1250ºF(540-680ºC) as per required properties.

Machinability of 9840 steel:

This alloy may be readily machined, preferably from a coarse pearlitic structure.

Weldability of 9840 steel:

pre-heat and post-weld stress relief are recommended for welding of this alloy. Welding should not be carried out in the hardened and tempered condition.