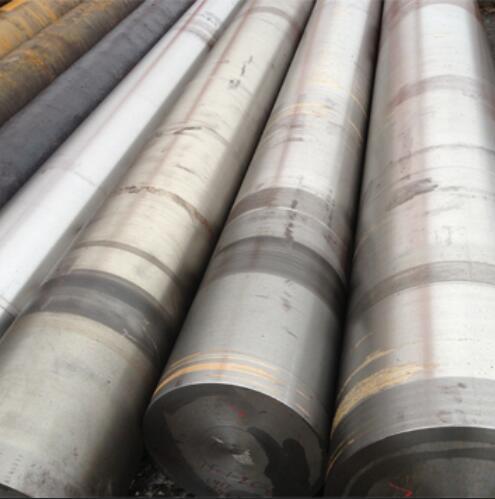

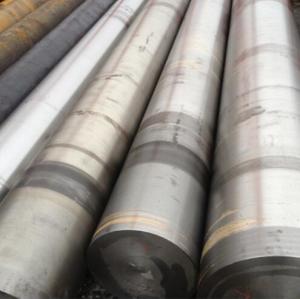

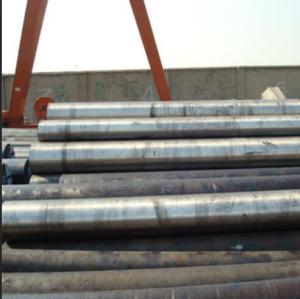

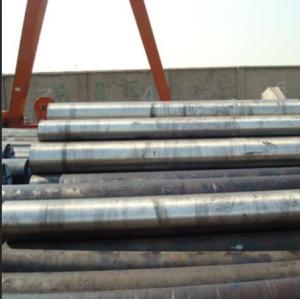

1045 G10450 1.1191 C45E S45C 1.0503 C45 Hot Forged Steel Round Bar

- Model

- 1045 CK45 080M46 S45C

Item specifics

- OD range:

- 80-1200 mm

- Delivery condition:

- hot forged+normalized

- Surface condition:

- Black

Review

Description

Introduce of 1.1191 steel:

DIN 1.1191 C45E Steel is a general carbon engineering steel according to DIN Germany standard. It’s one kind of high strength carbon steel which is mainly used after quenched and tempered. The 1.1191 steel has a certain shape and toughness and high strength. After QT, C45E steel can obtain good comprehensive mechanical properties. The welding performance of 1.1191 steel is not so good. This material needs to be preheated before welding, and carry on the annealing treatment after welding in order to eliminate the welding stress.

Applications of 1.1191 Steel:

DIN 1.1191 steel is applied to manufacture high strength movement parts,such as air compressor,piston pump,the impeller of a steam turbine,heavy duty and general machinery of the rolling shaft,connecting rod,worm,rack,gear,etc.

Chemical Composition of 1.1191 steel:

C: 0.42-0.50; Si: max0.40; Mn: 0.50-0.80; P: max0.030; S: max0.035; Cr: max0.40; Ni: max0.40; Mo: max0.10;

Equivalent Grades of 1.1191 steel:

AISI/ASTM: 1045, Germany: CK45, BS: 080M46, JIS: S45C, UNI: C45

Form of 1.1191 Steel:

Round / Square / Flat Bars, Shafts, Rollers, Blocks

Size of C45E Steel:

– As Forged

Round bar: Size: Dia.80-1,000mm, Length: 3,000-10,000mm

Square bar:Size: 150×150-600×600mm, Length: 3,000-8,000mm

(Forged Flat Bars, Shafts, Rollers and Blocks can be Customized)

– As Rolled

Round Bar

Size: Dia.10-300mm, Length: 3,000-10,000mm(can be Customized)

Mechanical Properties of C45E+QT:

Tensile strength: 600MPa

Yield point: 355MPa

Percentage reduction of area after fracture: 40%

Elongation after fracture: 16%

Impact test(+20°C): Transverse – 14J; Longitud – 39J

Quenched and Tempered (+QT) of 1.1191 Steel:

1. Increase the temperature slowly up to 840°C;

2. Soak at this hardening temperature and quench 1.1191 steel in the oil;

3. Cool down to 20°C in the air;

4. Heat uniformly to the tempering temperature of 600°C;

5. Hold at this temperature for 2 hours per 25mm thickness

6. Withdraw from the furnace and cool in the air.

Normalizing (+N) of DIN C45E Steel:

1)Heating din 1.1191 to 850°C;

2)Cool C45E material down to 20°C quickly in the air.