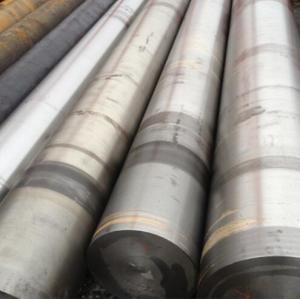

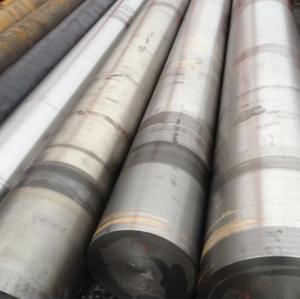

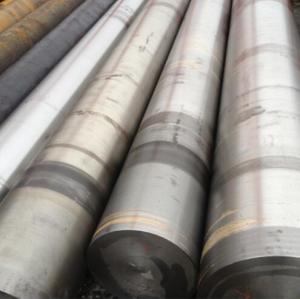

AISI SAE 4137 4137H 4137M Hot Forged Q+T Alloy Steel Round Bar for Oil and Gas Servies

- Price

- US $1500

- Model

- 4137 4137H 4137M

- MOQ

- 1 metric ton

Item specifics

- Steel grade

- 4137 4137H 4137M

- Applications

- Heavy Duty Shafts, Gears, Axles, Spindles, Couplin

- Heat treatment

- Normalized,Quenching and Tmenpering

- Surface condition

- Black or bright surface

- Standard

- ASTM A26

Review

Description

4137H forged steel bars Q+T SAE 4137H is an H-Steel grade Alloy Steel. It is commonly called SAE 4137H Chromium-molybdenum steel.SAE 4137H offers good ductility and shock resisting properties combined with resistance to wear. With these characteristics it is a popular high tensile engineering steel with a tensile of 850°-1000N/mm². At low temperatures it has reasonably good impact properties. It is also suitable for a variety of elevated temperature applications. For maximum wear and abrasion resistance the steel can be nitrided to give a shallow depth wear resistant case. Flame or induction hardening of 708M40T can give a case hardness of 50HRc or higher.

This alloy finds applications in the aerospace, oil and gas, auto and defense industries. It is used in the production of forged shafts, spindles, fixtures, jigs and collars.

Steel |

C |

SI |

MN |

Cr | Mo | P | S |

4137/4137H/4137M |

0.35-0.40 |

0.15-0.35 |

0.70-0.90 |

0.80-1.10 | 0.15-0.25 | max0.03 | max0.03 |