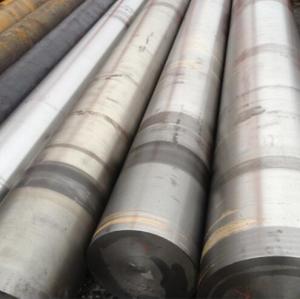

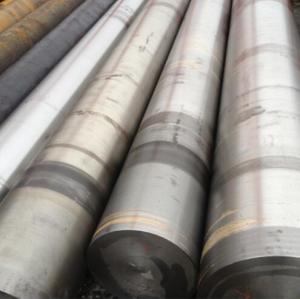

1.2379 D2 SKD11 Hot Forged Big Size ESR Cold Work Tool Steel Bar For Rollers

- Model

- 1.2379 D2 SKD11

Item specifics

- size range

- 300-1000mm

- shape

- round

- Process

- hot forged

- Delivery Condtion

- annealed

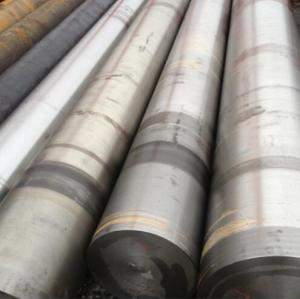

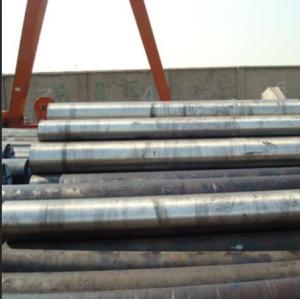

- Surface Condition

- smooth, bright

Review

Description

Introduce:

Cold rolling is a forming process which takes place below recrystallization temperature. It involves further reduction of already hot-rolled strip and a determining of the mechanical and technological properties of the same strip. Due to specific requirements during processing, cold rolling isregarded as a speciality within the diverse application areas of cold-work tool steels. They nevertheless have uses in other fields such as back-up rolls, straightening and section-bending rolls.

Standard:

Similar Grades:

ASTM | Material No. | DIN | EN |

D2 | 1.2379 | X155CrVMo12-1 | X160CrMoV121 |

Chemical Composition:

Grade | C | Mn | Si | P | S | Cr | Mo | V |

1.2379 | 1.45-1.6 | 0.20-0.60 | 0.10-0.6 | 0.03 max | 0.03 max | 11.0-13.0 | 0.7-1.0 | 0.7-1.0 |

Size & Process

Round Size Rnage:300-1000mm

Steel-making: EF/EAF+ESR

Process: Hot Forged

Delivery condition: Annealed

Surface condition: Bright

Heat treatment:

Annealed(+A) max: 255HB

Annealing: slow cooling at 650ºC-850ºCfurnace

Quenching: Preheat 650ºC~750ºC increased to 1010ºC, air-cooled, or into the 996ºC to keep the salt bath, then cooled.

Tempering: The cold work D2 tool steel general tempering temperature is 170ºC-190ºC , Double tempering of Double tempering of D2 tool steel is recommended.