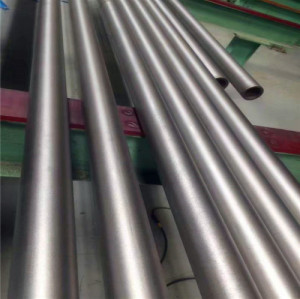

Fushun Drawn Over Mandrel Round DOM Steel Tubing

- Model

- Fushun Drawn Over Mandrel Round DOM Steel Tubing

Item specifics

- OD Size

- 10-300mm

Review

Description

DOM Tubing (Drawn over Mandrel) is a cold drawn 1020 to 1026 or ST52.3 grade electric resistance welded tube with all the flash removed prior to drawing to size. Cold drawing DOM to size allows for higher yield and tensile strengths. In comparison to other tubing, DOM is produced to more exact OD and ID tolerances. This allows for minimal machine time and has the highest weld strength possible.

*DOM tubing is made from 1020 / 1026 or ST52.3 Steel

*Meets ASTM A513 Type 5

*Cut to length service available

*Suitable to hone sizes

*Custom sizes available upon request

*All the common off road sizes available

Benefits of DOM Tubing (Drawn over Mandrel):

*Uniform wall thickness with close OD and ID tolerances

*Uniform grain structure and controlled hardness

*High Yield and Tensile Strength

*Smooth and Clean OD and ID surfaces

*OD and ID concentric

*Excellent machining characteristics

APPLICATIONS

*Hydraulic Cylinders

*Auto and Truck Axles

*Suspension parts and shock absorbers

*High Speed Shafts and rollers

*Bearings and Spacers

*Roll cages

*Agricultural components and many other machined tubular parts.

Shipping and Packaging

In today's competitive business environment, companies ranging from OEMs to hydraulic repair shops require fast supply chain responses from their vendors. In addition to large inventory and same day processing and shipping capabilities, we have partnered with some of the best in the freight handling industry to ensure your orders are shipped on time and in good condition.

All products are shipped considering method of cartage in appropriate packaging to protect from damage. Special overseas packaging is available.

DOM Tubes are packaged in either cardboard tube, cardboard tube and waterproof paper, or cardboard tube and wood crates.