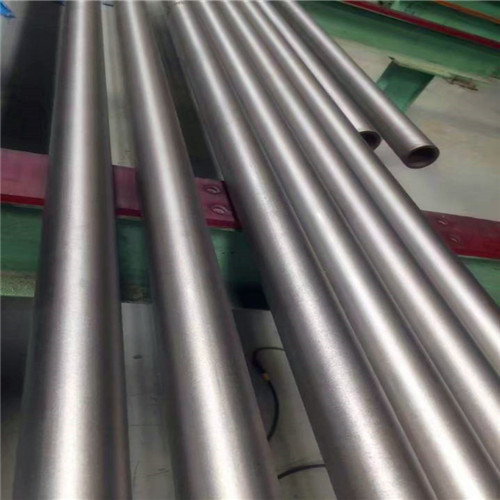

Fushun Precision Cold Drawn Seamless CDS Steel Tubing

- Model

- Fushun Precision Cold Drawn Seamless CDS Steel Tub

Item specifics

- OD size

- 10-300mm

Review

Description

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn steel tube. Produced from piercing hot rolled bar stock, the cold drawing process increases the tube's physical properties reducing the cost of machine time. Cold drawn seamless tubing provides a better uniformed OD and ID, enhanced machinability, increased strength, and tighter tolerances compared to hot finish seamless products.

Benefits of Cold Drawn Seamless Mechanical Tubing:

*Superior surface finish

*High yield strength

*Dimensional accuracy and excellent micro-structure uniformity

*Enhanced machinability

*High strength to weight ratio

*Tight tolerances, resulting in reduced machine time

*Possible spiraling eccentricity inherent in product

APPLICATIONS

*Hydraulic cylinders

*Rollers

*Structural applications

*Truck and Automotive parts

*Heavy equipment

*Agricultural components

Shipping and Packaging

Shipping In today's competitive business environment, companies ranging from OEMs to hydraulic repair shops require fast supply chain responses from their vendors. In addition to large inventory and same day processing and shipping capabilities, we have partnered with some of the best in the freight handling industry to ensure your orders are shipped on time and in good condition.

All products are shipped considering method of cartage in appropriate packaging to protect from damage. Special overseas packaging is available.

DOM Tubes are packaged in either cardboard tube, cardboard tube and waterproof paper, or cardboard tube and wood crates.and Packaging