30CDV12-30 Hot Work Tool Steel

Review

Description

30CDV12-30 Hot Work Tool Steel

Premium Tungsten-Free CrMoV Steel from FUSHUN METAL

Steel Grade Introduction and Applications

30CDV12-30 (also known as 32CrMoV12-28, 2365 ISO-B, H10, BH10) is a tungsten-free special hot work tool steel on a CrMoV base supplied by FUSHUN METAL. This premium steel grade offers exceptional toughness and is highly insensitive to thermal shock, making it not susceptible to heat cracking. The steel is particularly suitable for water cooling applications, providing reliable performance in demanding high-temperature environments.

FUSHUN METAL ensures consistent quality and reliable supply of this specialized hot work tool steel, meeting the stringent requirements of modern industrial applications. The CrMoV composition provides optimal balance between hardness, toughness, and thermal stability for demanding hot work applications where thermal shock resistance is critical.

Primary Applications:

Pipe extruders, extrusion stems, liners and die holders

Pipe mandrels and hot drawing mandrels

Part stamping dies for non-ferrous heavy metals

Forging tools for Hatebur presses

Non-ferrous heavy metal pressure die-casting

Heavy-duty forging operations and die inserts

Chemical Composition, Physical Properties & Heat Treatment

Chemical Composition (AFNOR Standards)

| Element | C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.28-0.35 | 0.10-0.40 | 0.15-0.45 | ≤0.030 | ≤0.020 | 2.70-3.20 | 2.50-3.00 | 0.40-0.70 |

| Typical Analysis | 0.30 | 0.30 | 0.30 | 0.025 | 0.003 | 3.00 | 2.80 | 0.60 |

Physical Properties (Reference Values)

| Property | 20°C | 250°C | 500°C |

|---|---|---|---|

| Thermal Expansion (10⁻⁶/K) | 10.7 (20-100°C) | 11.5 (20-250°C) | 12.3 (20-500°C) |

| Thermal Conductivity (W/mK) | 30.0 | 33.0 | 34.0 |

| Young's Modulus (GPa) | 210 | 195 | 172 |

Heat Treatment Parameters

| Treatment | Temperature | Duration | Cooling | Result |

|---|---|---|---|---|

| Soft Annealing | 800°C | 1h/25mm | Furnace | Max. 229 HB |

| Stress Relieving (Annealed) | 650°C | 1h/50mm | Furnace | Stress Relief |

| Stress Relieving (H&T) | 550°C | 1h/50mm | Furnace | Stress Relief |

| Hardening | 1040°C | 30s/mm | Oil/Air/Vacuum | Max. 52 HRC |

| Tempering | See Curve | 1h/25mm | Air | 30-48 HRC |

High-Temperature Yield Strength (0.2% Proof Stress)

| Hardness Level (MPa) | 450°C | 500°C | 550°C | 600°C |

|---|---|---|---|---|

| ~1570 | 1080 | 960 | 800 | 640 |

| ~1370 | 930 | 870 | 710 | 590 |

| ~1230 | 790 | 730 | 510 | 340 |

Delivery Condition: 30CDV12-30 is supplied by FUSHUN METAL in annealed condition to maximum 229 HB for optimal machinability. Hardened and tempered to customer specification available on request. Pre-heating of tools recommended at 250-350°C for working applications.

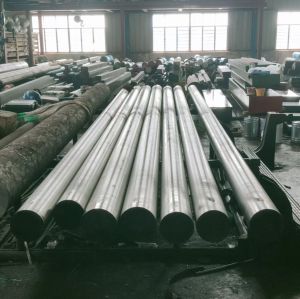

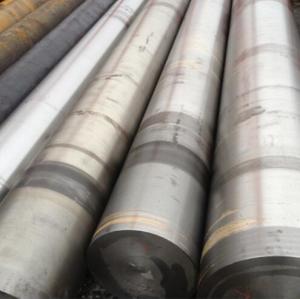

Available Sizes from FUSHUN METAL

FUSHUN METAL maintains comprehensive inventory of 30CDV12-30 hot work tool steel in various sizes to meet diverse industrial requirements. Our standard sizes are readily available from stock for immediate delivery.

Standard Stock Sizes Available:

Round Bars: Diameter 15mm to 500mm, Length up to 6000mm

Flat Bars: Thickness 15mm to 350mm, Width up to 1200mm

Square Bars: 20mm × 20mm to 400mm × 400mm

Plates: Thickness 25mm to 450mm, Custom dimensions available

Forged Blocks: Custom forged blocks for large die and mould applications

Stock Advantage: Standard sizes are maintained in inventory for fast delivery and competitive pricing, ensuring minimal lead times for critical projects.

Custom Manufacturing: We accept custom orders for non-standard dimensions and special requirements. Please contact us to discuss your specific size requirements and production capabilities.

Quote Request: Contact FUSHUN METAL today for competitive pricing on standard sizes or custom manufacturing solutions for your 30CDV12-30 applications.

FUSHUN METAL Advantages

Fast Stock Delivery

Extensive inventory of 30CDV12-30 ensures rapid delivery of standard sizes, minimizing your project downtime and maintaining production schedules for critical hot work tool manufacturing and die-casting operations.

Integrated Manufacturing Network

Strategic partnerships with leading Chinese specialty steel producers ensure consistent quality, competitive pricing, and reliable supply chain management for premium hot work tool steels like 30CDV12-30.

Precision Machining Services

Complete machining capabilities including turning, grinding, and finishing services to deliver ready-to-use hot work tool components, saving time and costs for downstream customers in extruder, die-casting, and forging industries.

Technical Expertise

Professional technical support and consultation services to help customers optimize heat treatment parameters, tool design, and application-specific solutions for 30CDV12-30 in demanding hot work environments with thermal shock resistance requirements.

Contact FUSHUN METAL Today

Experience the FUSHUN METAL advantage in hot work tool steel supply. Contact us for competitive quotes, technical consultation, and reliable delivery solutions for your 30CDV12-30 requirements in extruder tools, die-casting moulds, and forging applications.